Precision sheet metal processing with comprehensive facilities and reliable technology.

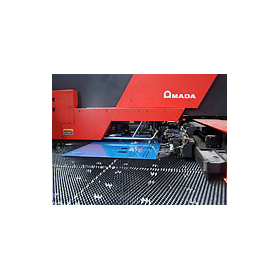

Our company is equipped with specialized facilities for sheet metal processing, led by our single punch, allowing us to respond quickly and accurately to a wide range of sheet metal processing needs. Furthermore, we do not solely rely on equipment performance; we maximize the high technical skills of our processors to perform precise and accurate processing. We can accommodate various lot sizes, shapes, diverse applications, and materials. Please feel free to contact us with your requests. 【Single Punch Features】 ■ AMADA HMX3510NT ■ No need to change molds according to the shape of processed parts, achieving a significant reduction in lead time. ■ Capable of processing materials from 0.5mm to 3.2mm, allowing us to flexibly meet our customers' diverse needs. *For more details, please download the PDF or feel free to contact us.

Inquire About This Product

basic information

【Main Equipment】 ■ Single Head Punch Press AMADA HMX3510NT ■ Press Brake AMADA HDS-8025NT ■ CO2 Laser Processing Machine AMADA FO-2412 ■ Deburring Machine FLEADER ■ Gantry Type Five-Sided Machining Center OKUMA MCR-A5C X4000 Y2000 Z1200, etc. *For more details, please download the PDF or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please download the PDF or feel free to contact us.

catalog(1)

Download All CatalogsCompany information

Our company has been engaged in sheet metal processing as a manufacturer since 1973, handling everything from prototypes to finished products. Subsequently, with the industry's transformation, we not only continued our sheet metal business but also introduced a gantry five-sided machining center in 2009. We have integrated large frame processing for can manufacturing, automation, and labor-saving devices, enabling us to carry out a consistent production process from "order" to "design," "sheet metal," "welding," "machining," "painting," and "delivery."

![Micron-level precision, high difficulty × short delivery time! Precision cutting processing [Processing case examples available].](https://image.mono.ipros.com/public/product/image/2070746/IPROS9035842601074547405.png?w=280&h=280)