A treatment that sterilizes E. coli and Staphylococcus aureus with ultra-fine unevenness! Since it is not a coating, it does not peel off, and there are no resistant bacteria as no chemicals are used.

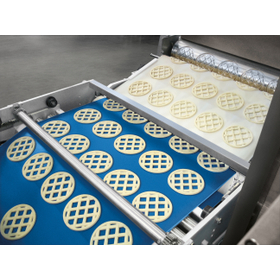

The micro-dimple treatment creates uneven surfaces that are comparable in size to general bacteria. For example, bacteria can move freely on a stainless steel mirror surface, but on stainless steel treated with micro-dimples, the formed unevenness obstructs their ability to move and act freely. Additionally, the uneven surfaces are thought to inhibit flagellar movement, leading to self-damage in bacteria, which results in antibacterial effects.

Inquire About This Product

basic information

In 2012, a technical university in Australia announced in Nature that the nanometer-scale pillar structures present on the surfaces of cicadas and dragonflies have antibacterial properties. When observed from the side, they appear pillar-like, and when viewed from above, they look like fine irregularities. The antibacterial effect is achieved by creating these nanometer-scale irregularities through micro-dimple processing. In antibacterial efficacy evaluation tests (conducted by MISTEC, Kanagawa Prefectural Institute of Industrial Technology), it was found that out of 330,000 E. coli, almost none remained after 8 hours. The antibacterial activity value exhibited an astonishing effect of over 3.0.

Price information

Approximately 15,000 yen for A4 size.

Delivery Time

P3

Applications/Examples of results

Handle, grip, faucet, wire belt, mesh, hopper, chute, nozzle, kitchen knife, cutter, blade, general cooking utensils.

catalog(1)

Download All CatalogsCompany information

As a leading company in WPC processing, we achieve further reduction in friction and improvement in wear resistance and seizure resistance by combining it with other surface treatments such as DLC/PVD coating. WPC processing continuously shot-blasts metal surfaces with micro-sized media, generating residual compressive stress on the surface while simultaneously forming countless micro-dimples, significantly improving the fatigue strength and sliding characteristics of sliding components. Fujii WPC Co., Ltd. boasts a wide range of processing achievements in industrial fields, from automotive parts to molds, cutting tools, and other tools, as a leading company in WPC processing. With composite processing using DLC coating, high-quality coatings are now possible even on aluminum, which was previously challenging. Additionally, by applying WPC as a pre-treatment for PVD coatings on molds, cutting tools, and other tools, we can further enhance the excellent performance of PVD. The lifespan of automotive parts, metal components, molds, cutting tools, and other tools can be multiplied several times! Composite processing combined with nitriding, carburizing, high-frequency hardening, and coating is expected to provide further durability and friction reduction. We offer short delivery times and can accommodate orders starting from one piece, as well as composite processing.

![Metal surface treatment "WPC treatment" [Since it is surface modification, it will not peel off!]](https://image.mono.ipros.com/public/product/image/f0f/2000250614/IPROS6282443061634856549.jpg?w=280&h=280)