Brass, copper alloys, brass materials, automotive parts, EV, prototype and mass production support for busbars!

Mitsui Sumitomo Metal Mining Copper Alloy, Mitsubishi Copper Alloy, PMC materials, and next-generation copper-aluminum clad material "CCA".

Also for prototyping busbars, terminals, and terminal materials! Coils, plates, and plating materials can be procured in necessary quantities when needed through our in-house inventory and procurement network.

Tatsumiya Metal's metal material sales can provide high-quality non-ferrous metal materials and plated materials with short delivery times, thanks to our extensive in-house inventory and slitting equipment. Typically, the delivery time for standard material supply, such as coil materials, takes about one week to ten days. However, at Tatsumiya Metal, we maintain inventory and perform in-house processing, allowing us to ship on the same day as the order and deliver the next day at the earliest. (Note: The usual delivery time is 4 to 5 days.) The minimum lot size for coil materials is usually 2 kg/mm. For prototypes, we can provide materials in units of a few centimeters, allowing us to respond to shipping needs based on application and urgency. We also quickly accommodate requests for prototype materials in sheet form. This approach reduces inventory risk, enabling material supply only as needed when required. **Features** - Stock of various copper products and plated materials - Support from in-house and external slitting facilities - Through our supply network, we can provide and propose prototype materials in coil form and standard-sized sheets beyond our in-house inventory. - We have established a supply system through a network with domestic and international copper product manufacturers. Additionally, we can accommodate both prototypes and mass production of thick copper materials for busbars, which have seen increasing demand in recent years. *For more details, please download the catalog or contact us.*

Inquire About This Product

basic information

【Available Materials Example】 ■ Copper: C1020, C1100, C1220, PTC (equivalent to C1100) ■ Copper-aluminum clad material "CCA" ■ Brass: C2600, C2680, C2801 ■ Tin-plated ■ Phosphor bronze: C5191, C5210 ■ Aluminum, stainless steel, titanium, etc. also available 【Slitting Processing Range】 ■ Thickness: 0.1mm to 3.5mm (in-house) 2.0mm to 5.0mm (partner factories) ■ Width: 5mm to 400mm ■ Tolerance: Width ±0.1mm * Please inquire even if outside this range. 【Standard Sheet Materials】 Small sheet: 365×1200 Large sheet: 1000×2000 Cut sheets: Can be provided in necessary amounts, not limited to the above standard sizes. 【Delivery Time & Quantity】 ■ Delivery Time: Fastest same-day shipping upon order, next-day arrival. Usually 4 to 5 days after order. ■ Quantity: Minimum lot standard, unit weight 2kg/mm or 4kg/mm * Small quantity for prototypes, such as a few meters or centimeters, is possible. * We excel in unit weight splitting and detailed cutting! (Example: Dividing a 1c×100kg coil into 5 equal parts, 5c×20kg) * For more details, please download the catalog or contact us.

Price information

Prices may fluctuate due to copper market conditions and quantities, so please feel free to contact us.

Delivery Time

P1

Applications/Examples of results

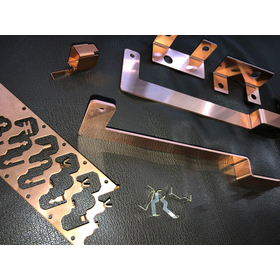

Automotive components, automotive electrical components, bus bars and terminals (for automobiles, construction machinery, and motorcycles), home appliances, office automation equipment, digital devices, low-voltage components, heat exchanger parts, clothing components, spring products, etc. Additionally, it is now possible to achieve weight reduction and cost reduction for copper materials that could not be aluminumized in the past by using fully coated copper-aluminum clad material "CCA."

Detailed information

-

Copper alloy slit coil Copper, brass, phosphor bronze, copper alloy slit coil

-

Copper, brass, copper alloys, phosphor bronze Copper, brass, copper alloys, phosphor bronze slit coil

-

Copper alloy with tin plating Brass with tin plating, copper

-

Bus bar Connector Terminal Press processing

-

Lightweighting and cost reduction of pure copper components using copper-aluminum clad materials.

Line up(8)

| Model number | overview |

|---|---|

| C1100R | Main stock sizes: 1/4H; 0.5, 0.8, 1.0 mm; 1/2H; 0.8, 1.0, 1.5, 2.0 mm, etc. Please inquire about other thicknesses. |

| C1020R | In addition to the main sizes of 1.0, 2.0, 2.5, and 3.0 mm, we also have rare steel types such as O material in 0.2 to 0.3 mm. Of course, please inquire about other options! |

| Next-generation copper-aluminum clad material CCA | Busbars, coils, flat wires, etc. |

| Reflow tin plating | This is a brass strip with reflow tin plating: C2600, C2680, thicknesses of 0.5, 0.64, 0.8 mm, etc. Slitting available for immediate delivery from the coil center. Prototype support is also OK. |

| C2680R | O material, 1/2H, H, EH, thicknesses of 0.15 to 2.0 mm. Slitting available nationwide. We also accept sample material requests. |

| C2801R | O material, 1/4H, thicknesses of 0.3, 1.0, 1.2 mm, etc. Stock and slitting support available. |

| C1220R | Primarily 1/4H; 0.2 to 0.3 mm, but please inquire about other options! |

| Phosphor bronze | Currently provided by various manufacturers such as JX Metals, Harada Copper Works, Seihou Metals, PMC, etc. |

catalog(12)

Download All Catalogs

Company information

<Metal Materials Trading Division> With a rich inventory and four slitting facilities, we supply from the Higashi-Osaka Coil Center to the entire country. We specialize in the sales of copper alloy materials and non-ferrous metal materials. We are also actively proposing the next-generation copper-aluminum clad material "CCAC" in collaboration with Applied Composite Material Corp. <Metal Processing Division> We excel in processing small quantities of various metal pipes. Our diverse technologies include coil winding, R-bending, various bending processes, and welding. We handle everything from one-off parts used in heat exchanger components and machinery to larger quantities for automotive, consumer, and housing equipment. In the world of bending processing, where small lots are common, the presence or absence of molds becomes quite important. We mix our own molds and equipment with those from partner factories to provide tailored proposals. Additionally, our NC automatic lathe precision cutting processing leverages the procurement advantages unique to Tatsumiya, which has a metal materials trading division, enhancing customer satisfaction through technical expertise, procurement capabilities, and cost efficiency. With over 90 years of establishment as a processing trading company, we view the 100-year mark as a milestone and will continue to build a great company in the future.

![Auto connector, piping automatic switching device, Quitto [Case study collection available]](https://image.mono.ipros.com/public/product/image/aee/2001134281/IPROS13093723827804871931.jpg?w=280&h=280)