Case Studies of 'Ultra-Precision Machining of Difficult-to-Cut Materials' Introduced by Suwa's Hirabayashi Seiki

Please consult us for processing a variety of small parts, special products, and difficult-to-cut materials.

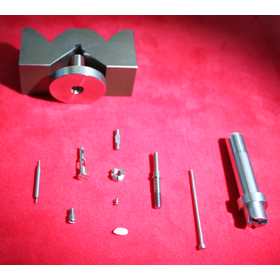

The "Processing Case Collection of Hirabayashi Seiki" is a collection of processing examples that includes knurling, screw rolling, hydraulic equipment parts, machining of difficult-to-cut materials, and solenoid processing, which are our areas of expertise. 【Examples Included】 ◯ Knurling ◯ Screw rolling using secondary processing machines ◯ Hydraulic equipment parts requiring ultra-high precision ◯ Solenoid processing ◯ Machining of difficult-to-cut materials ◎ For more details, please refer to the PDF document or feel free to contact us.

Inquire About This Product

basic information

For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

catalog(1)

Download All CatalogsCompany information

Our company, based on exceptional technical capabilities, owns 24 state-of-the-art NC machining machines, along with one cam-type machine, allowing us to handle a wide range of orders from small quantities of various parts to mass-produced components. Furthermore, we process a variety of materials, from aluminum and brass to difficult-to-machine materials such as SUS (stainless steel) and pure iron. Additionally, with the introduction of ultrasonic cleaning machines, we can ensure environmentally friendly and reliable cleaning in the final finishing process of our products, which has been well received by our users.

![[Technical Column] Methods to Achieve Cost Reduction in Machining](https://image.mono.ipros.com/public/product/image/57a/2001136593/IPROS22191564573442251696.png?w=280&h=280)

![[Processing Example] Acrylic Transparent Plate, Pipe](https://image.mono.ipros.com/public/product/image/f36/2001431710/IPROS38535136783994113743.jpeg?w=280&h=280)

![Micron-level precision, high difficulty × short delivery time! Precision cutting processing [Processing case examples available].](https://image.mono.ipros.com/public/product/image/2070746/IPROS9035842601074547405.png?w=280&h=280)