We propose suitable shapes in response to customer requests! Consistent support from design and production to testing and analysis.

Our company consistently handles everything from the design and production of motorcycle sprockets to testing and analysis. By proposing suitable shapes in response to customer requests, we have gained high trust. In addition to domestic motorcycle manufacturers in Japan, we are also adopted by major motorcycle manufacturers around the world, including those in North America, Europe, Southeast Asia, Central and South America, and India. [Features] ■ Comprehensive support from design and production to testing and analysis ■ Proposing suitable shapes in response to customer requests ■ Adopted by major motorcycle manufacturers worldwide *For more details, please feel free to contact us.

Inquire About This Product

basic information

For more details, please feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

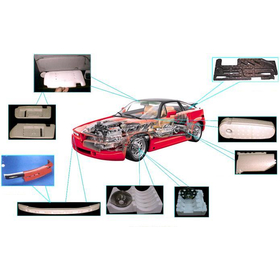

【Usage】 ■Automobiles, motorcycles, construction machinery, agricultural machinery, industrial equipment, etc. *For more details, please feel free to contact us.*

catalog(1)

Download All CatalogsCompany information

The origin of Sunstar Giken dates back to 1932 when it began selling bicycle parts. Subsequently, the company successfully manufactured and sold its own bicycle rubber adhesive (glue for tires and tubes). Utilizing the production equipment for the metal tubes that contained the rubber adhesive, they commercialized what is now known as Sunstar toothpaste, which became the foundation of Sunstar Co., Ltd. Meanwhile, the bicycle parts manufacturing and sales business later shifted to metal parts for motorcycles, establishing the foundation of the current Sunstar Giken Co., Ltd. Since then, the company has responded to the changing needs of the times by supplying OEM parts such as motorcycle sprockets, brake discs, and outboard motor gears to domestic and international two-wheeled manufacturers, holding a top-class market share. They excel in integrated production from pressing, heat treatment, cutting, gear cutting, to polishing using coil materials with thicknesses ranging from 4mm to 13mm, and can handle a wide range of materials including carbon steel, stainless steel, and aluminum in collaboration with multiple material manufacturers. The equipment includes a diverse range of facilities from large presses of 150 tons to 2000 tons, machining centers, laser processing machines, hobbers, NC lathes, polishing machines, and high-frequency hardening, enabling processing tailored to customer needs.

![[Cost Reduction Case] Short Delivery Time Sprocket Production](https://image.mono.ipros.com/public/product/image/0bc/2001140589/IPROS28523150606487865249.png?w=280&h=280)

![[S Case] Sprocket](https://image.mono.ipros.com/public/product/image/8e1/2000728895/IPROS60204441371772216966.png?w=280&h=280)