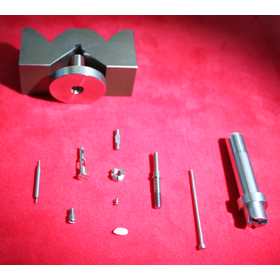

From processing a variety of small parts to special product processing and difficult-to-cut materials. Leave precision parts processing to us.

Hirabayashi Seiki was founded in 1970 as a specialized company for precision parts processing. Thanks to years of accumulated technology, we have continuously evolved our techniques in partnership with our customers, and we hope to reflect our experience and know-how in providing better precision parts for your products. Additionally, at our company, responding to numerous strict requests has made "fast production" a standard practice, and we are prepared to meet tight deadlines, even in emergencies or critical situations. If you think it might not be possible, please feel free to consult with us. 【Business Activities】 ■ Precision parts processing ■ Turning and rolling processing of difficult-to-cut materials *For more details, please refer to the PDF document or feel free to contact us.

Inquire About This Product

basic information

【Manufacturing by Hirabayashi Seiki】 ■ Capable of processing difficult-to-machine materials in iron and non-ferrous metals ■ Equipped with processing capabilities ranging from φ2mm to φ25.0mm ■ Cutting processing related to automotive, solenoids, hydraulics, construction machinery, weaving machines, optics, music boxes, medical devices, and semiconductor manufacturing machine parts ■ Technology for knurling and thread rolling processing for difficult-to-machine materials ■ Production support that ensures "quality, cost, and delivery time" to compete with overseas companies *For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

catalog(1)

Download All CatalogsCompany information

Our company, based on exceptional technical capabilities, owns 24 state-of-the-art NC machining machines, along with one cam-type machine, allowing us to handle a wide range of orders from small quantities of various parts to mass-produced components. Furthermore, we process a variety of materials, from aluminum and brass to difficult-to-machine materials such as SUS (stainless steel) and pure iron. Additionally, with the introduction of ultrasonic cleaning machines, we can ensure environmentally friendly and reliable cleaning in the final finishing process of our products, which has been well received by our users.

![[Case Study on Problem Solving] Proposal for Aluminum Material for Components](https://image.mono.ipros.com/public/product/image/812/2000997706/IPROS28383635581373475589.png?w=280&h=280)

![Precision Parts Processing and Jig Manufacturing [Main Product Examples]](https://image.mono.ipros.com/public/product/image/68b/2000359152/IPROS1955932759378822399.PNG?w=280&h=280)

![Stainless Steel Processing Service [Processing Example: Combination Parts of Resin and SUS]](https://image.mono.ipros.com/public/product/image/729/355124014/IPROS_16927811093561176000.jpg?w=280&h=280)

![Micron-level precision, high difficulty × short delivery time! Precision cutting processing [Processing case examples available].](https://image.mono.ipros.com/public/product/image/2070746/IPROS9035842601074547405.png?w=280&h=280)