Energy saving is not just about the compressor! 【Super energy-saving refrigeration dryer】

Did you know that energy savings can also be achieved on the dryer side? It eliminates waste during the heat exchange from refrigerant to compressed air and minimizes the operation of the built-in compressor.

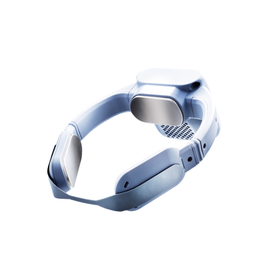

Introduction to the revolutionary ultra-energy-saving 'Air Dryer' handled by Nikikoso Co., Ltd. Conventional refrigerated dryers operate their built-in refrigerant compressors continuously, regardless of the load, resulting in electricity costs. The PCM series utilizes phase change materials (PCM) to absorb the load, allowing the built-in refrigerant compressor to operate only when necessary, significantly reducing electricity costs. While energy savings for air compressors are gaining attention, substantial energy savings are also possible on the dryer side. The selection of refrigerated dryers is typically based on the highest temperatures during summer. However, Japan experiences seasonal temperature variations and differences between daytime and nighttime temperatures. The average temperature in Tokyo is 15.4°C, which is considerably lower compared to the temperature used for selection. The PCM series stops the built-in refrigerant compressor during unnecessary times through temperature control, allowing for significant energy-saving effects on average throughout the year in environments with load fluctuations or temperature changes. 【Operating Principle of PCM Dryer】 ■ PCM is cooled by the refrigerant ■ Compressor stops when compressed air reaches 2°C ■ Compressed air is cooled by PCM ■ Compressor restarts when compressed air reaches 6°C

Inquire About This Product

basic information

The PCM series cools the refrigerant with a cooling agent (PCM) and stops the built-in refrigerant compressor when the temperature of the compressed air after cooling reaches 2°C. After that, it cools the compressed air using only the stored energy until the temperature of the compressed air rises to 6°C, at which point the built-in refrigerant compressor is restarted. In general, air-cooled refrigerated dryers use a pressure switch for the fan to control its operation. Depending on the usage environment, this pressure switch can be a major cause of failure in air-cooled refrigerated dryers. The PCM series controls the system using signals from temperature sensors and does not use a pressure switch for the fan, thereby increasing reliability.

Price range

P5

Delivery Time

※The standard delivery time is 2.5 months.

Applications/Examples of results

It is a refrigerated dryer for compressed air. Installed on the secondary side of the compressor, it is capable of drying compressed air by lowering the temperature to below 10°C, achieving a pressure dew point of 10°C.

Detailed information

-

This is a structural diagram (internal system diagram).

-

This is a comparison document of power consumption. When using the PCM series at an average of 15°C, it will drop to the green line.

catalog(4)

Download All CatalogsCompany information

Nikkiso Co., Ltd. has an Industrial Division that mainly handles pump products, an Aerospace Division that deals with carbon fiber components for aircraft, and a Medical Division that handles artificial dialysis devices. In the Industrial Division, in addition to pump products, we handle electronic component manufacturing equipment centered around isostatic pressing devices, water quality control equipment for thermal and nuclear power generation, and air dryers. While leveraging existing technologies, we are always challenging ourselves with new technologies through flexible thinking that is not constrained by conventional frameworks. To ensure the stable supply of high value-added products, we place great importance on our in-house training system and are committed to the guidance and development of young employees by veteran staff.