CO2 reduction of turbo refrigeration systems in the automotive industry is here.

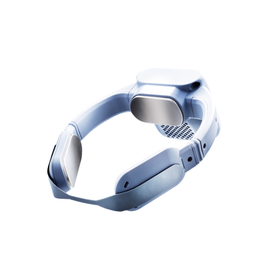

Frontier Technology XAC

In the automotive industry, there is still significant potential for efficiency improvements in measures against heat exchanger contamination for painting lines and refrigeration equipment.

One of the main parts of a refrigeration unit, the condenser and evaporator, requires regular cleaning due to significant efficiency loss caused by dirt. If cleaned properly, the efficiency returns to normal; however, dirt begins to accumulate again immediately after restarting operation, leading to many cases where the unit operates in a low-efficiency state for most of the year. Our ball-type heat exchanger automatic cleaning device, XAC, eliminates waste caused by dirt by continuously and automatically cleaning the heat exchanger. For more details, please visit our website. ↓ http://www.frontiertechnology.co.jp/product/index.html

Inquire About This Product

basic information

What is the Ball-type Heat Exchanger Automatic Cleaning Device (XAC)? 〇 It is a device that continuously cleans the heat exchanger with a sponge ball. 〇 The only maintenance required is the replacement of the sponge ball. 〇 The ball replacement task is completed in 5 minutes. The introduction of XAC is expected to yield the following benefits: ◆ Energy-saving effects due to increased efficiency ◆ Reduction of CO2 emissions due to increased efficiency ◆ Reduction of downtime due to the elimination of cleaning ◆ Cost savings due to the elimination of cleaning ◆ Extended lifespan of the heat exchanger due to the elimination of cleaning ◆ Extended lifespan of the refrigerant compression compressor due to increased efficiency ◆ Freedom from cleaning schedules due to the elimination of cleaning

Price information

The price varies depending on the diameter of the customer's cooling water piping. It is possible to clean multiple refrigeration units with one system (multi-system). Please contact us each time.

Price range

P5

Delivery Time

※We will respond within usually three months.

Applications/Examples of results

Absorption chillers for hospitals, buildings, and commercial facilities Turbo chillers for automotive, semiconductor, food factories, and chemical plant production lines Large compressors for steel mills, chemical plants, and paper mills Generators for waste treatment plants and factory self-generation Even with the introduction of high-performance chillers, if the condenser and absorber (also proven for evaporators) are dirty, their capabilities cannot be fully realized. Please consider upgrading to chillers that do not get dirty through ball cleaning for your heat exchangers.

catalog(6)

Download All CatalogsCompany information

The costs of electricity and gas for air conditioning have become a significant issue that cannot be ignored. No matter how efficient a refrigeration unit is, if the heat exchanger is dirty, its performance can be halved. Even with regular brush cleaning, it may remain dirty for most of the operating period, leading to increased maintenance costs. For those who have not encountered a method to "keep the heat exchanger clean," I hope to introduce a way to maintain the heat exchanger in a clean state without incurring high costs for water treatment, without needing to perform brush cleaning once a year, or chemical cleaning every few years.

![[Heat Stroke Prevention] Indoor Use & Outdoor Installation Compatible Windbreak Room / Break Room](https://image.mono.ipros.com/public/product/image/2001600195/IPROS5208935003205325095.png?w=280&h=280)