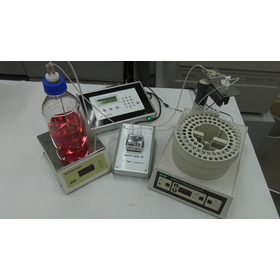

We have developed a sampling unit for sampling into sterile centrifuge tubes. It is easy to control and uses our company's HPLCap for connection.

The optimal sampling unit for sampling culture media. It allows for sampling of culture media into 50ml conical tubes. The tubes are made of Teflon, and the connectors and liquid contact parts are made of PEEK and Teflon. The cap utilizes our convenient and easy-to-connect HPLCap technology. When used in conjunction with our sampling device, it enables sampling of up to four samples over time. The control employs a rotary pump with pulse motor control, allowing for the collection of culture media with digital condition settings (time, speed, collection volume, waste volume, etc.). Videos are currently available on our website and YouTube (SystemBiotics channel)!

Inquire About This Product

basic information

- Liquid transfer is done using a peristaltic rotary pump. - The motor is a pulse motor, allowing for precise control. - The tube is primarily made of silicone. - The connector is made of PEEK. - The valve is a pinch valve. - The connection uses our proprietary technology, a Teflon HPLCap. - It enables sampling into 50ml centrifuge tubes. - Up to four centrifuge tubes can be used for sampling. - A waste port is provided to dispose of residual liquid in the tube. - The use of a syringe filter greatly enhances the possibility of sterility.

Price range

P3

Delivery Time

※The delivery time may vary depending on the quantity, so please feel free to contact us.

Applications/Examples of results

- Sampling of culture medium - Sampling of reaction solution

catalog(3)

Download All Catalogs

Company information

We are working on the automation of biotechnology using various technologies. All aspects of hardware design, circuit board design, and software development are carried out with our in-house technology. We are focusing on the development of prototypes and trial machines for bio equipment and process management devices. We can respond flexibly and quickly to customization requests. Our main activities involve collaborative research and development related to bio automation with various research institutes, including RIKEN, and universities. We have accumulated a large library of hardware and software, enabling faster development. We also conduct equipment evaluations using essential reagents for bio equipment development in our unique joint lab at the Toin University Medical Engineering Center. We have extensive development experience in contracted development of new bio equipment for NEDO over many years, as well as custom development of ELISA devices and ELISA washers. Please feel free to contact us regarding the development and prototyping of new equipment. Since we handle all electrical, mechanical, and software development in-house, we specialize in automation of bio equipment, automation of analytical instruments, automation of process management, and protocol development on a custom basis. You can trust us with the development of pneumatic systems such as caps and handy connectors.

![[Comprehensive Catalog] Coolant Treatment Equipment (Product List)](https://image.mono.ipros.com/public/product/image/4e7/2000845788/IPROS02176169969756745687.png?w=280&h=280)

![14 Manufacturing Managers Speak / Coolant Sludge [Successful Recovery Case]](https://image.mono.ipros.com/public/product/image/338/2001402875/IPROS7746502535285026449.jpg?w=280&h=280)