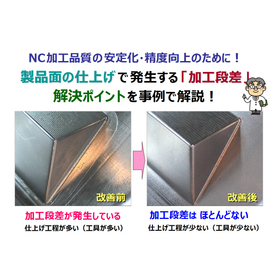

To improve the quality and precision of NC machining! What are the key points for resolving machining step differences?

What are the key points for solving the 'processing step' that is likely to occur in product finishing? We are currently offering materials such as "Case Studies on Troubleshooting in Mold Processing"!

In finishing processes, if there are many leftover steps and a large number of tools are used, thermal displacement of each axis and the main spindle of the machine can easily cause "machining steps" on the finished surface. Therefore, to reduce or eliminate machining steps, it is essential to minimize the types and number of tools used during the finishing process. 【Five Important Points in Finishing Processes】 ◇ Tool Selection 1. Use tools with good cutting performance and edge accuracy (no variation in R accuracy or outer diameter). 2. Use tools with low deflection and high rigidity (use a pencil neck when the protrusion is long). 3. Use tools with coatings suitable for the work material (especially for soft steel). ◇ Machining Methods and Cutting Conditions 1. Ensure that roughing before finishing does not leave any material in corners or recesses. 2. In semi-finishing, process the entire area to a uniform finishing allowance (do not leave large bumps). 3. In finishing, avoid high-speed rotation to minimize the expansion and contraction of the machine spindle. 4. Use cutting fluid to improve chip removal and lubrication of the cutting edge. For more details, please refer to the PDF document. If you have any questions, please feel free to contact us.

Inquire About This Product

basic information

The key to solving issues in mold processing is to improve machining through "how to create CAM programs"! If you are struggling with the skill enhancement of CAM operators, please feel free to consult us.

Price information

Please feel free to contact us.

Delivery Time

Applications/Examples of results

Mainly focusing on automotive and motorcycle-related parts, large aluminum die-casting molds, plastic molds (resin molds), precision molds for electronic components, press prototype molds using castings and zinc alloys, and forging molds made with high-hardness heat-treated materials, etc.

Detailed information

-

Manufacturing is about building people! From basic knowledge of cutting processes to practical application techniques useful on-site, we provide hands-on instruction in CAM skills.

-

If you have any questions regarding the use of tools, processing conditions, or processing methods, please feel free to contact us.

catalog(20)

Download All Catalogs

News about this product(2)

Company information

"Tool Communication" Our products are born from communication with our customers. To provide products and services that are trusted and genuinely satisfying, OSG values the dialogue with customers through tools, which we call "Tool Communication." "Shaping Your Dreams" We want to shape the dreams of each and every customer. Driven by this desire, we continue to take on challenges and support the global manufacturing industry on a worldwide scale. The era is experiencing a significant paradigm shift in cutting-edge technologies such as electric vehicles, healthcare, and clean energy. We will collectively work on the development of advanced technologies that capture the needs and seeds of future technologies, including research on new materials, the latest coating technologies, and environmentally friendly products.