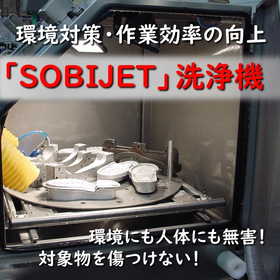

It automatically cleans grease stains from products, tools, and recycled parts with powerful cleaning. It operates economically with temperature and time settings.

The dedicated rotating nozzle and rotating basket allow for cleaning from multiple directions, thoroughly washing the interior of the cylinder. High-temperature water cleaning is achieved using an electric heater, and combined with a specialized cleaner, it effectively removes dirt. Since the cleaning water is a circulating system from an internal tank, constant connection to a water supply is not necessary. It is economically feasible with only periodic cleaning water replacement. Due to the use of high-temperature water, evaporation drying occurs after cleaning. This method is particularly effective for parts with complex shapes and uneven surfaces. We also offer a specialized cleaner that maintains cleaning power while minimizing foaming.

Inquire About This Product

basic information

Specifications excerpt Cleaning liquid temperature: MAX 70°C Heating method for cleaning liquid: Plug-type electric heater Maximum weight of items to be cleaned: MAX 80kg Dimensions of cleaning turntable: Φ450mm × H120mm Electrical capacity: Three-phase 200V - 4KW (peak) Volume of circulation tank: 55ℓ Dimensions of the machine: Length 900mm × Depth 785mm × Height 962mm Weight of the machine: 160kg There is also a larger model, GE-65.

Price information

Please contact us.

Price range

P5

Delivery Time

※Usually around 2 months after the order is received.

Applications/Examples of results

Cleaning of tools and rebuilt parts at maintenance workshops Cleaning during the attachment and detachment of parts, removal of old oils and greases Regular cleaning of lighting and visibility components in railway and aviation sectors Regular cleaning maintenance of production equipment parts Cleaning maintenance of applicators and other attachment and detachment jigs

catalog(1)

Download All CatalogsCompany information

Our company is engaged in the development, manufacturing, sales, and maintenance of harness production-related equipment, including terminal crimping inspection devices, sensor units, and various control units. We also accommodate custom requests, provide consultation on construction methods, and offer development and manufacturing as well as model selection. Please feel free to contact us with any inquiries.