A transportation packaging proposal that achieves efficient transport while maintaining the scratch-free and aesthetic qualities of sheet metal parts!

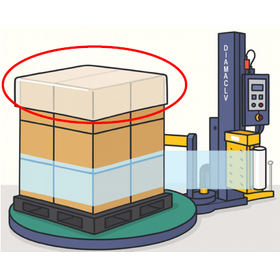

The transportation packaging material introduced this time is a product used for transporting sheet metal parts for precision equipment. We have been asked to propose efficiency improvements over conventional transportation packaging methods, and we would like to present a case study of our proposal. In the case of sheet metal parts, there are often specifications to ensure that the surface is free from scratches for aesthetic reasons. Therefore, we proposed a method of stacking the parts in a windmill arrangement with cushioning materials inserted, so that the parts do not touch each other and get scratched. As a result, we successfully accommodated four pieces in one box, which has improved transportation efficiency by up to twice compared to conventional products. [Case Overview] ■ Size: W650mm × D450mm × H400mm ■ Additional Function: Efficiency in logistics and space-saving ■ Material: Made of PP, honeycomb core material ■ Industry: Automotive parts manufacturing factory ■ Product Category: Returnable box *For more details, please refer to the PDF document or feel free to contact us.

Inquire About This Product

basic information

For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

catalog(1)

Download All CatalogsCompany information

Whether it is [one-way] or [commuting], whether cushioning is necessary, and the effects of static electricity... the optimal materials vary depending on the contents. We will propose improvements to the packaging format for the 2024 issue. Tohoku Ueno Co., Ltd. will utilize the many packaging examples we have cultivated so far and various new materials developed in recent years to solve environmental issues, offering the best combinations. We will consider all aspects, including cost, material selection, processing methods, and environmental factors, to meet our customers' needs. We will conduct drop tests using the drop tester from Ransomont, analyze the shock waveforms with test partners, and propose optimal cushioning packaging designs.

![[Case Study of Packaging Design Improvement] LCD Module Shipping Box](https://image.mono.ipros.com/public/product/image/59a/2000594330/IPROS25749887650321091657.png?w=280&h=280)

![[Case Study of Packaging Design Improvement] Dedicated Shipping Box for Industrial Products (Mecha-Shear Shipping Box)](https://image.mono.ipros.com/public/product/image/bfd/2000594335/IPROS74550045054221004806.png?w=280&h=280)

![[Case Study of Packaging Design Improvement] Proposal for Enhancing Loading Efficiency of Automotive Parts Returnable Boxes](https://image.mono.ipros.com/public/product/image/e60/2000594346/IPROS69342574190291977800.png?w=280&h=280)

![[Case Study of Packaging Design Improvement] Delivery Box for Nozzle Air Hose](https://image.mono.ipros.com/public/product/image/070/2000594350/IPROS67266086521752460630.png?w=280&h=280)

![[Special Feature on Delivery Boxes] Make shipping easier with compact packaging!](https://image.mono.ipros.com/public/product/image/236/2001011946/IPROS89356342000349011070.png?w=280&h=280)

![[Product Example] Delivery Box <Packed in a state of "jumping out" from the "body">](https://image.mono.ipros.com/public/product/image/b68/2001058519/IPROS43402444251260132085.jpeg?w=280&h=280)

![[Product Example] Delivery Box <Efficient Packaging of Products with Complex Shapes>](https://image.mono.ipros.com/public/product/image/4de/2001058517/IPROS46264223902940886068.jpeg?w=280&h=280)

![[Packaging Example] Returnable Box for Automotive Parts](https://image.mono.ipros.com/public/product/image/adb/2001023918/IPROS47345305207195697276.png?w=280&h=280)

![Stretch Film "Komaki" [Industry First! Optimal for ECO and Work Efficiency!]](https://image.mono.ipros.com/public/product/image/474/2000317425/IPROS17167699807860247107.jpeg?w=280&h=280)