Automatic measurement of characteristics such as angle error measurement! It also includes functions for parameter settings.

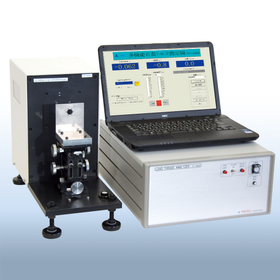

Celtechnos Co., Ltd. handles the stepping motor torque measurement device 'TC-9000'. The torque resolution is ±0.1%, and the torque measurement range is from 10% to 100% of the rated value. The angle resolution is 0.001 degrees, and the sampling interval is 2 msec. This product automatically measures characteristics such as pull-in measurement, settling measurement, and angle error measurement. 【Features】 ■ Parameter setting ■ CSV file saving ■ Data loading ■ Meter screen ■ Zero point correction ■ Channel switching *For more details, please refer to the PDF document or feel free to contact us.

Inquire About This Product

basic information

【Automatically Measured Characteristics】 ■ Pull-in Measurement ■ Pull-out Measurement ■ Settling Measurement ■ Angle Error Measurement ■ Detent Torque Measurement ■ Holding Torque Measurement ■ θ-T Measurement ■ Constant Torque Measurement ■ Torque Step Measurement *For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

catalog(2)

Download All CatalogsCompany information

Celtechnos Co., Ltd. is a company that provides optimal measurement environments for customers through precision measurement technology utilizing load cells and the development of real-time control software. We manufacture torque measuring machines, torque sensors, motor torque measuring machines, other test machines for specific applications, and durability testing machines. We also offer torque calibration and contract torque measurement services. ◆ Main Products TEST CABIN: The industry's first standard torque measuring machine Visualizing the dynamic characteristics of gear reducers The "TEST CABIN Precision Gear Reducer Transmission Characteristics Measuring Machine TC25, TC45" covers 10 essential evaluation items for precision gear reducers (efficiency, angular transmission error, rigidity, lost motion, no-load running torque, starting torque, reverse starting torque, reverse efficiency torque, repeatability position accuracy, shaft resonance) and can graphically display torque, angle, and efficiency. With precision measurement using load cells and real-time control software, it is possible to visualize the dynamic characteristics of gear reducers. The TC200, which can automatically measure angular transmission error and rigidity for inspection lines, is also part of our lineup. In addition to flexible equipment design according to measurement specifications, we also undertake contract torque measurement.

![[Product Page] "Flexible Combination Torque Measurement System" Product List](https://image.mono.ipros.com/public/catalog/image/01/b81/769918/IPROS35939376756000591015.jpeg?w=120&h=170)

![[Test Cabin] Standard Torque Measurement Device Measurement Case Collection](https://image.mono.ipros.com/public/product/image/dcd/2000603002/IPROS76503876438422503849.png?w=280&h=280)

![[For the pharmaceutical manufacturing industry] Digitizing entry management in oxygen-deficient hazardous work.](https://image.mono.ipros.com/public/product/image/20a/2001525768/IPROS14827379347403299223.jpg?w=280&h=280)

![[For the food manufacturing and beverage manufacturing industry] Digitizing the management of oxygen deficiency hazard work in tank entry.](https://image.mono.ipros.com/public/product/image/bf8/2001525769/IPROS12773363766147418267.jpg?w=280&h=280)

![[Video] Useful Video on Electrical Conductivity Measurement (Desktop Electrical Conductivity Meter)](https://image.mono.ipros.com/public/product/image/59289/IPROS12986349931594449331.png?w=280&h=280)