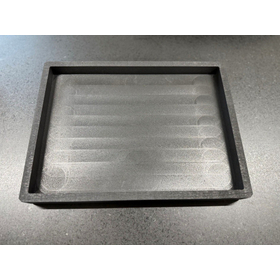

This is a carbon tray that can be used at high temperatures (700℃ and above). It is ideal for environments that are susceptible to the effects of oxygen, such as powder metallurgy sintering and ceramic sintering.

Carbon has limitations in its use at temperatures exceeding 450°C due to significant oxidation occurring in an atmosphere where oxygen is present. In many cases, metals or ceramics have been used. Metals have the issue of increased weight due to high density, while ceramics face problems with brittleness and breakage. Our carbon, treated with a sealed membrane process, can be used at high temperatures above 450°C while suppressing the reaction between carbon and oxygen, allowing the properties of carbon to be utilized effectively.

Inquire About This Product

basic information

The carbon is treated with a "composite ceramic sealed coating," which isolates the carbon components from the outside. Therefore, it is not affected by oxidation. Additionally, to suppress the bonding with metal elements that easily react with carbon, it also demonstrates advantages as a tray for metal sintering. ◎ Powder metallurgy sintering tray ◎ MIM sintering tray ◎ Ceramic sintering tray ◎ Can also be used as an alternative to alumina thermal spray carbon.

Price range

Delivery Time

Applications/Examples of results

Powder metallurgy sintering tray MIM sintering tray Ceramic sintering tray Alternative to alumina thermal spray carbon

catalog(1)

Download All CatalogsCompany information

We are a specialized manufacturer of carbon fiber molded insulation materials, felt, CC composites, and high-temperature carbon products with over 25 years of experience in the United States and Europe. For many years, we have been adopted by vacuum furnace manufacturers in the U.S. and Europe as genuine internal furnace components. Our strengths include short delivery times, low prices, and unique pressure-resistant and wear-resistant materials. Since 2018, we have been introducing our products as a sales and inventory base in Japan and the surrounding Asian region. This marks our new market entry in Asia, as we previously had no sales network there. Please feel free to contact us if you have any inquiries.

![[Book] Firing and Sintering Techniques for Ceramics and Metals (No. 2237)](https://image.mono.ipros.com/public/product/image/451/2001129378/IPROS62003523544646185428.gif?w=280&h=280)

![[Case Study] "Ceramics" Pipe Clogging, Countermeasure Case / MAGPICKER](https://image.mono.ipros.com/public/product/image/2072749/IPROS15928645237023093400.jpg?w=280&h=280)