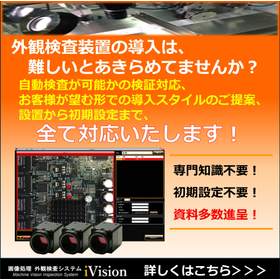

In the AI era, appearance inspection is supported with a one-stop service from consulting in pre-verification to system construction!

The "Appearance Inspection Service Using Deep Learning" is highly flexible, accommodating various patterns such as specifications, shapes, structures, surface shapes, and finishes. Compared to visual inspection and conventional image inspection, it enables automated inspection without variability, eliminating reliance on individual operators. It allows for model construction with minimal data and development in a short period. Furthermore, it offers high flexibility with additional learning and model updates. For those looking to implement an automated inspection system or struggling with the personalization and accuracy of appearance inspections, our company will support you from preliminary verification to system construction. 【Features】 ■ Capable of handling diverse and challenging situations ■ Can start with minimal data ■ Automation of feature extraction ■ Instant judgment, efficiency, and high precision ■ Additional learning and model updates available ■ Relatively low barriers to implementation *For more details, please refer to the PDF materials or feel free to contact us.

Inquire About This Product

basic information

【Specifications】 ■ AI learning model development ■ Judgment software ■ Inspection hardware (camera, lighting, dedicated PC) * ■ Integration with existing equipment * * Regarding hardware and equipment integration, we can also propose products from partner companies after consulting with the customer. * For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

【Purpose】 ■ Various visual inspections ■ Alternative to visual inspections ■ Realization of full inspection guarantee *For more details, please refer to the PDF document or feel free to contact us.

catalog(1)

Download All CatalogsCompany information

Our company develops and sells a "Maintenance Management System" for managing and operating various plants, factories, and other facilities and assets. Currently, this system is undergoing significant evolution into one that incorporates IoT technologies, such as sensor information and input from tablet devices, as well as AI technologies like machine learning, featuring functions for failure prediction and automatic scheduling. Additionally, as part of the recent trend towards digital transformation (DX), there is a growing movement to digitize and automate manufacturing processes and research and development sites in factories to enhance operational efficiency. In line with this trend, our company provides a solution aimed at improving efficiency in research and development environments, known as the Laboratory Information Management System (LIMS), which includes features such as workflow management, data tracking, data management, data analysis, and integration of electronic lab notebooks.

![Dimension measurement and image inspection service [Quantitative measurement used in the image!]](https://image.mono.ipros.com/public/product/image/b4b/2000310467/IPROS937071718587747199.jpg?w=280&h=280)