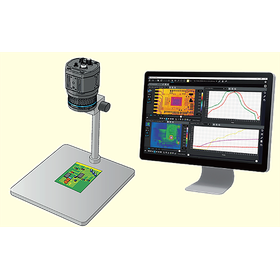

This is a thermographic inspection system that visualizes temperature state changes in the production line and distinguishes between good and defective products.

This is a device that uses thermal images measured by a thermography camera for inspection, judgment, output, and data storage. While typical handheld thermography is intended for temporary measurements, our system enables continuous inline inspection by combining it with a compact fixed thermography camera. *Note: Not all thermography cameras are compatible; only specified models from our company can be used. The following improvements are expected as a result of implementation: - Full inspection: Automatically inspects by inputting synchronization signals from external sensors or machines. - Prevention of defective product discharge: Can detect temperature anomalies and output errors to external devices. - Traceability: Allows for follow-up verification through the storage of thermal images with data. - Data collection: Capable of collecting a large amount of temperature data that can lead to future improvements.

Inquire About This Product

basic information

Number of camera connections: Up to 4 units Temperature measurement range: -40°C to 2000°C (depending on the connected camera) Temperature resolution: < 0.03°C Inspection items: Maximum temperature, minimum temperature, average temperature, differential measurement, area measurement, etc. Interface: DIO, Ethernet Others: Data storage function available, PLC integration possible *Customization is possible according to customer specifications. *Product demonstrations and on-site testing are available at any time.

Price range

Delivery Time

Applications/Examples of results

Main Applications 1. Automotive Industry - Die-casting machine mold temperature monitoring - Hot press steel temperature monitoring - Processing temperature inspection during laser welding - Heating temperature inspection during high-frequency quenching - Friction temperature inspection during FSW joining 2. Food Industry - Hot melt defect auditing - Heat seal bite inspection - Cup seal welding defect inspection 3. Chemical Products Industry - Bank control inspection of calendar rolls - Temperature variation inspection in resin sheet manufacturing process - Waviness inspection of rubber sheets (edge detection) 4. Electronic Components Industry - Lubricant application defect inspection - LED electrode defect inspection - Wafer heating state inspection 5. Steel Industry - Iron door temperature inspection of ladles - Iron skin temperature monitoring of torpedo cars - Fire monitoring in stockyards - Temperature management of steel slabs in continuous casting lines - Management of trolley line abnormalities in overhead cranes For more details on applications, please contact us directly.

catalog(1)

Download All CatalogsCompany information

We are a technology trading company that creates new value in response to the times, from infrastructure to the latest technologies.