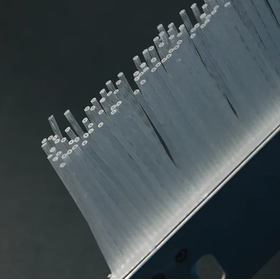

Metal-free finishing is possible! The arrangement of the brush bristles is available in various types such as parallel and staggered.

At Nonomiya Sangyo Co., Ltd., we handle "insert brushes." This product can be manufactured using materials for the brush base such as resin, wood, iron, aluminum, rubber, leather, and Bakelite, which can be drilled. We offer a variety of manufacturing methods including machine planting, two-part splitting, hand planting, and insertion types. We can produce various brush shapes. 【Features】 ■ Can be reused multiple times without damaging the insert base ■ Can be inserted even with thin insert bases ■ If the insert base can be drilled, it can be hand-planted onto anything ■ All components including the insert base, bristle material, and sewing thread can be made from resin products ■ Metal-free finishing is possible *For more details, please refer to the PDF document or feel free to contact us.

Inquire About This Product

basic information

【Other Features】 - Each hole is securely planted one by one, resulting in minimal hair breakage and almost no hair loss. - Acid-resistant brushes can be made without using metal parts. - Various manufacturing methods such as machine planting, two-part splitting, hand planting, and insertion type allow for the production of a wide range of brush shapes. *For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

catalog(1)

Download All CatalogsCompany information

Nonomiya Sangyo Co., Ltd. is a company that designs and manufactures industrial brushes such as deburring brushes, polishing brushes, cleaning brushes, and static electricity removal brushes, as well as brush automation machines. We offer easy and cost-effective solutions for static electricity removal and deburring using brushes. Our industrial brushes can be custom-made in quantities ranging from one to many, tailored to applications such as cleaning, static electricity removal, and deburring. Additionally, we provide free testing for deburring and surface treatment (polishing and cleaning), although shipping costs will be the customer's responsibility. We design and manufacture industrial brushes and brush automation machines according to our customers' needs.