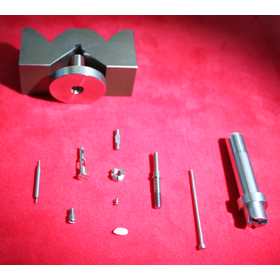

Materials used include "S45C, SUS303, SUS304"! Here are examples of hexagonal hole broach manufacturing.

We would like to introduce a case study on the production of device parts for the semiconductor equipment industry. We received a request stating, "We would like you to process from material to delivery according to the length and diameter based on the application." When performing hexagonal machining, there is a tendency for burrs to occur with the conventional processing method. Our company has devised ways to prevent burrs and contamination from affecting the process. The work sizes range from hexagonal H1.5 to H6.0, and φ25 to φ5. 【Case Details】 ■ Production capacity: 15,000 to 35,000 pieces/month (depending on material diameter) ■ Processed materials: S45C, SUS303, SUS304 ■ Machines used: All processing done using NC machining ■ Work sizes ・Hexagonal from H1.5 to H6.0 ・φ25 to φ5 *For more details, please refer to the PDF document or feel free to contact us.

Inquire About This Product

basic information

【Overview】 ■Request Details - We would like you to process materials according to length and diameter based on their intended use and deliver them. ■Features and Innovations - When performing hexagonal processing, there is a tendency for burrs to occur with the conventional processing method; however, we ensure that no burrs or contamination that could affect the product are produced. *For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

catalog(1)

Download All CatalogsCompany information

Our company, based on exceptional technical capabilities, owns 24 state-of-the-art NC machining machines, along with one cam-type machine, allowing us to handle a wide range of orders from small quantities of various parts to mass-produced components. Furthermore, we process a variety of materials, from aluminum and brass to difficult-to-machine materials such as SUS (stainless steel) and pure iron. Additionally, with the introduction of ultrasonic cleaning machines, we can ensure environmentally friendly and reliable cleaning in the final finishing process of our products, which has been well received by our users.

![<Production Example> [For the Semiconductor Equipment Industry] Hexagonal Hole Broach](https://image.mono.ipros.com/public/catalog/image/01/513/583660/IPROS52022364294719509018.jpeg?w=120&h=170)

![Cutting processing example: Resin processing [Galaepo]](https://image.mono.ipros.com/public/product/image/035/2000139451/IPROS6910203245771032807.jpg?w=280&h=280)