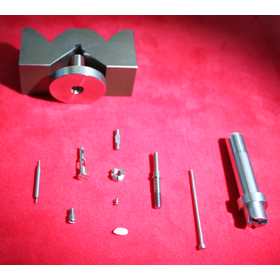

<Production Example> Tapered flat flounder knurling and slotted hole processing (rotating shaft component)

A shaft is made using a NC machining machine, and then processed with a knurling machine! This is a production example with a work size of φ6.

Here is an example of the production of a rotating axis component. "We would like you to process the shaft with a knurling at a specified pitch of 0.42." "We would like you to include a slit at the tip for rotation and deliver it." The original slit processing is used when fixing an object, but for this component, there is a cross hole perpendicular to the slit, and we processed it so that a pin can be pressed in, allowing the counterpart component to rotate. 【Case Details】 ■ Production capacity: 1,000 to 3,000 pieces per unit ■ Processing materials: SUS416/SUS303 ■ Machines used: Knurling machine → The shaft was made on a CNC machine, followed by processing on the knurling machine ■ Work size: For this product, φ6 *For more details, please refer to the PDF document or feel free to contact us.

Inquire About This Product

basic information

【Overview】 ■Request Details - I would like the shaft to be processed with knurling at the specified pitch of 0.42. - Please include a slit at the tip for rotational movement upon delivery. ■Features and Innovations - A cross hole is drilled perpendicular to the slit, allowing a pin to be press-fitted so that the mating part can rotate. *For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

catalog(1)

Download All CatalogsCompany information

Our company, based on exceptional technical capabilities, owns 24 state-of-the-art NC machining machines, along with one cam-type machine, allowing us to handle a wide range of orders from small quantities of various parts to mass-produced components. Furthermore, we process a variety of materials, from aluminum and brass to difficult-to-machine materials such as SUS (stainless steel) and pure iron. Additionally, with the introduction of ultrasonic cleaning machines, we can ensure environmentally friendly and reliable cleaning in the final finishing process of our products, which has been well received by our users.