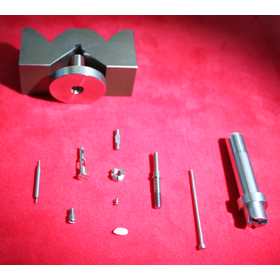

<Production Example> [For Industrial Machinery] Precision Flat Fish Scale Knurling Processing (Rotating Shaft Component)

Possible to accommodate pitch width and other specifications according to instructions! An example of a blank processing that allows for insert molding.

Here is an example of manufacturing rotating shaft components for industrial machinery. We received requests such as "Please perform the knurling according to the drawing" and "I would like the knurling pitch of 0.6 at the tip for delivery." Since it will be an iris knurling, care was taken to ensure that the peaks do not get flattened, and to attach a resin gear that rotates at the tip, measures were taken to prevent the gear from moving. Blank processing was carried out to enable insert molding. 【Case Details】 ■ Production capacity: 1,000 to 2,000 pieces/month (can accommodate pitch width and other specifications as needed) ■ Processing material: SUS430 ■ Machines used: All processing done in our factory ■ Work size: Outer diameter φ6 (consultation available regarding size / up to φ10 possible) *For more details, please refer to the PDF document or feel free to contact us.

Inquire About This Product

basic information

【Overview】 ■Request Details - I would like the knurling to be done according to the drawing. - Please include a knurling pitch of 0.6 at the tip for delivery. ■Features and Innovations - Since it will be an iris knurling, care is taken to prevent the peaks from being flattened. - A resin gear for rotating the axis is attached at the tip, ensuring that the gear does not move. - Blank processing has been performed to enable insert molding. *For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

catalog(1)

Download All CatalogsCompany information

Our company, based on exceptional technical capabilities, owns 24 state-of-the-art NC machining machines, along with one cam-type machine, allowing us to handle a wide range of orders from small quantities of various parts to mass-produced components. Furthermore, we process a variety of materials, from aluminum and brass to difficult-to-machine materials such as SUS (stainless steel) and pure iron. Additionally, with the introduction of ultrasonic cleaning machines, we can ensure environmentally friendly and reliable cleaning in the final finishing process of our products, which has been well received by our users.

![<Production Example> [For Industrial Machinery] Advanced Flat Fish Scale Processing (Rotating Shaft Component)](https://image.mono.ipros.com/public/catalog/image/01/fd9/587721/IPROS99541200134278217188.jpeg?w=120&h=170)

![<Production Example> [For the Semiconductor Equipment Industry] Hexagonal Hole Broach](https://image.mono.ipros.com/public/product/image/aa8/2000609356/IPROS17772176708235510555.png?w=280&h=280)

![[Processing Example] Knurling on Outer Diameter and End Face](https://image.mono.ipros.com/public/product/image/201/2000765239/IPROS98796571036998063128.png?w=280&h=280)

![[For Buyers] Aluminum A5052 Machining Factory Distribution BCP China](https://image.mono.ipros.com/public/product/image/c52/2000537465/IPROS20234588998982283540.png?w=280&h=280)

![[Free Offer] Prevent Blade Troubles in Production Equipment! Non-Stick Thin Film Coating](https://image.mono.ipros.com/public/product/image/fde/2000612726/IPROS23915370847246220159.jpeg?w=280&h=280)

![[Free Giveaway] Non-Stick Coating | Prevent Blade Troubles in Production Equipment!](https://image.mono.ipros.com/public/product/image/a78/2000619955/IPROS37607432622075090550.jpeg?w=280&h=280)

![[Surface Treatment Case] Surface treatment that streamlines the manufacturing process of lithium-ion batteries.](https://image.mono.ipros.com/public/product/image/604/2000700111/IPROS81671406460541521470.jpeg?w=280&h=280)