Microreactors, micro-scale CSTRs, mixer-settlers, and other devices utilizing microfabrication can be experienced in the experimental lab.

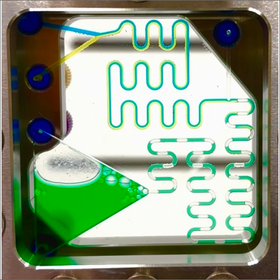

There are two types of continuous reactors (flow reactors)! 1. Microreactor (Tubular Reactor: PFR) - Precise control and acceleration of mixing, heat transfer, and reactions ⇒ High performance and high functionality - Enables operation under harsh conditions such as nitration (avoiding explosions) ⇒ Improved safety - Miniaturization of equipment and systems ⇒ Resource and energy savings 2. Microscale (Continuous Stirred Tank Reactor: CSTR) - A fully mixed continuous stirred tank reactor miniaturized for experimental use - Extremely smooth transition from batch synthesis to continuous flow synthesis - Capable of heating, cooling, high pressure, microwave, light reactions, crystallization, etc. 3. Mixer Settler (Extraction, Separation, and Washing Device) - Suitable for continuous post-processing (extraction, washing, phase separation, etc.) after reactions - Generates a slug flow in a Y-shaped flow path, achieving continuous separation in tanks on the same plate - Possible to realize a flow process for post-processing by connecting devices in multiple stages ■ Equipped with various measurement and inspection instruments ■ Development, design, manufacturing, and sales are OK ■ Rentals available at the "Microreactor Research Lab" - Over 50 types of microreactors available *For more details, please refer to the PDF document or feel free to contact us.

Inquire About This Product

basic information

Standard Specifications 1. Microreactor Standard materials are SUS304 and SUS316, with compatibility for various materials such as titanium, Hastelloy, Inconel, niobium, tantalum, and glass. Standard type with a plate thickness and flow channel width of 0.2mm. Compatible dimensions: plate thickness from 0.05mm to 10mm, flow channel width from 0.04mm to 1mm. Can be disassembled for cleaning. 2. CSTR Materials include SUS316L, PTFE, and Teflon. Adjacent reaction vessels are connected. The volume of one reaction vessel is approximately 3ml, with a total volume of 20ml for 6 vessels. For synthetic scale, approximately 2ml x 6. 3. Mixer Settler Materials include SUS316L, Hastelloy, and glass. Flow rate: 0.3 to 10 mL/min. Extraction time: 0.2 to 3 min. Separation time: 0.5 to 3 min. Tube length: adjustable based on changes in settler plate thickness.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

catalog(3)

Download All CatalogsCompany information

Mac Engineering Co., Ltd. has been continuing its challenge for technological improvement under the spirit of intellectual bravery since its establishment in 1981, delivering courage and vitality from the manufacturing site to society. Providing consistent manufacturing with responsibility, quickly, with high precision and high quality from materials to the final process is both a characteristic and a strength of Mac Engineering. From now on, we are actively working on research and development of our original flow reactor products to create high-value-added products that not only continue and inherit the technologies we have cultivated so far but also possess uniqueness. You can experience continuous flow reactors in our in-house research lab. Mac Engineering will support the efficient development and testing to the next step. 【Main Member Organizations】 - iFactory - Flow Precision Synthesis Consortium (Flow ST) - Kinki Chemical Society - Flow Micro Synthesis Research Group (GRAMS) - Okayama Microreactor Network (Secretariat Company) - Chugoku-Shikoku Scientific Instruments Association

![Mac Technical Report [Theme: On Continuous Flow Synthesis]](https://image.mono.ipros.com/public/catalog/image/01/9bc/600749/IPROS6719212266666474758.jpeg?w=120&h=170)

![Mac Technical Report [Products1] Continuous Flow Experimental Equipment Lineup](https://image.mono.ipros.com/public/product/image/0bb/2000651250/IPROS45899967626992438449.png?w=280&h=280)