Inspection equipment that supports the quality inspection process of printed circuit board suppliers!

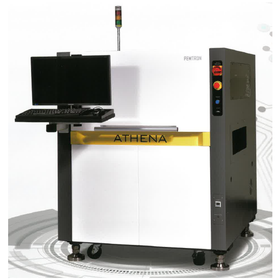

"ATHENA" is a 3D appearance inspection machine for printed circuit boards (raw substrates) that utilizes unique 3D inspection technology and advanced lighting technology to achieve surface appearance inspection and measurement that was impossible with conventional 2D inspections. By inspecting invisible defects in 2D and 3D, it supports the quality inspection processes of printed circuit board suppliers. Thanks to moiré technology, it can detect dents, bubbles, foreign objects, and other issues in 3D that cannot be found through 2D inspections. 【Features】 - Surface appearance inspection and measurement with advanced technology: 2D lighting, 3D lighting, coaxial lighting - High-speed 3D inspection and measurement - Surface inspection (2D, 3D, AI): defect inspection of substrates - More detailed inspection of the field of view (FOV) - Inspection based on substrate information (Gerber data) *For more details, please download the PDF or feel free to contact us.

Inquire About This Product

basic information

【Specifications (Excerpt)】 ■Camera: 12 Mega Pixels ■Resolution: 7μm, 5.5μm, 2.3μm ■FOV: 2.8cm×2.1cm, 2.3cm×1.7cm, 1.0cm×0.7cm ■Processing Speed: 11.76cm²/sec, 7.82cm²/sec, 1.3cm²/sec ■Lens: Telecentric Lens, etc. *For more details, please download the PDF or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

【Inspection Targets】 ■ Plated areas (Gold, Copper, Solder, Tin) ■ Solder resist areas (Green, White, Black) ■ Silk areas *For more details, please download the PDF or feel free to contact us.

catalog(1)

Download All CatalogsCompany information

Our company mainly provides fully automatic printed circuit board inspection equipment. In addition, we are involved in building smart SMT lines, including software development, and developing production systems for manufacturing processes. Please feel free to contact us first.

![[Explanatory Material] ATHENA Surface Inspection Equipment](https://image.mono.ipros.com/public/product/image/552/2000711484/IPROS69835068231261544611.png?w=280&h=280)

![[Video Now Available] Appearance Inspection Device 'M-CIS'](https://image.mono.ipros.com/public/product/image/b90/2000576260/IPROS3516131519794065525.jpg?w=280&h=280)

![[Exhibition] Introduction of Exhibited Products at the 40th Nepcon Japan](https://image.mono.ipros.com/public/product/image/75128/IPROS15158590780797094915.jpg?w=280&h=280)