Detect and notify pre-labor behavior with AI! Equipped with a new thermal camera.

"Ushi Waka" is a non-contact camera system that detects characteristic behaviors before calving and notifies via smartphone. It can be used at night just like during the day, as it analyzes based on thermal images. An AI trained on calving data accumulated from demonstration farms across the country accurately identifies characteristic behaviors before calving. 【Features】 ■ Reduced burden ■ Accident prevention ■ No burden on the cows ■ Increased productivity ■ Clear images for verification *For more details, please refer to the PDF document or feel free to contact us.

Inquire About This Product

basic information

【Other Features】 - Management of images and behavioral data sent from the image sensor in the cloud - Utilizing data for AI learning to improve the accuracy of detecting signs of labor - Feedback of improved software to the sensor - Ability to check the current status on a smartphone when an email arrives - Clear videos and activity levels are displayed, allowing for judgment of the timing of labor *For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

catalog(1)

Download All CatalogsCompany information

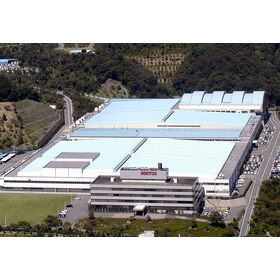

Our company has established a factory and system that can meet all the requests of companies looking for a reliable partner to outsource parts processing for the expansion of their product lineup. Please feel free to consult with us. --- ■ Production factory for highly controlled medical devices (Class III) In 2013, we were the first in Wakayama Prefecture to obtain a license for manufacturing and selling Class I medical devices, and in 2015, we also acquired ISO 13485 certification for the quality management system for medical devices. ■ Over 60 years of accumulated technical expertise We started with the manufacturing of photo processing equipment for stainless steel processing and have since engaged in the production of precision equipment with over 4,000 component parts. ■ A factory capable of parts processing We have the capability to produce various parts, including sheet metal, turning, milling, resin molding, and circuit board assembly. ■ Extensive development experience Photo processing equipment involves various technical elements, and we also have a track record in the development of applied medical devices and nursing care equipment.

![[Measurement System Example] Railway Vehicle Wheel Flat Detection](https://image.mono.ipros.com/public/product/image/d7f/2000601361/IPROS67390258834002783012.png?w=280&h=280)

![[For the pharmaceutical manufacturing industry] Digitizing entry management in oxygen-deficient hazardous work.](https://image.mono.ipros.com/public/product/image/20a/2001525768/IPROS14827379347403299223.jpg?w=280&h=280)

![[For the food manufacturing and beverage manufacturing industry] Digitizing the management of oxygen deficiency hazard work in tank entry.](https://image.mono.ipros.com/public/product/image/bf8/2001525769/IPROS12773363766147418267.jpg?w=280&h=280)