[Case Study of Packaging Design Improvement] Packaging Materials for Overseas Transport *For the Tohoku Region

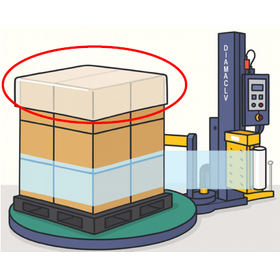

We will introduce a case study of a quality improvement proposal that successfully achieved export packaging of products without scratches or dirt.

We would like to introduce examples of packaging and packing improvements for imported products from Southeast Asia. The customer's request was, "The darts stand gets damaged during domestic transportation, which reduces its value as a product when it arrives in the country, so we want to address this issue." As the products inside the box were only secured with tape, we created new interior materials to prevent the products from moving. Additionally, since the products need to withstand stacking and will be delivered domestically via courier, we considered the size and shape of the cardboard box to meet these requirements. Furthermore, since the packaging is done in China, we selected materials that are easy to procure locally. *For more details, please refer to the PDF document or feel free to contact us.

Inquire About This Product

basic information

**Benefits of Packaging and Wrapping Improvements** - By enhancing the strength of the cardboard, products can be transported without damage, maintaining quality during domestic shipping. - Since the transportation is domestic, we propose using courier services to reduce shipping costs, leading to cost savings. - Although the structure is designed to withstand weight, material selection is also conducted to ensure that materials can be sourced from China, reducing procurement costs. *For more details, please refer to the PDF document or feel free to contact us.*

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

catalog(3)

Download All CatalogsCompany information

Whether it is [one-way] or [commuting], whether cushioning is necessary, and the effects of static electricity... the optimal materials vary depending on the contents. We will propose improvements to the packaging format for the 2024 issue. Tohoku Ueno Co., Ltd. will utilize the many packaging examples we have cultivated so far and various new materials developed in recent years to solve environmental issues, offering the best combinations. We will consider all aspects, including cost, material selection, processing methods, and environmental factors, to meet our customers' needs. We will conduct drop tests using the drop tester from Ransomont, analyze the shock waveforms with test partners, and propose optimal cushioning packaging designs.

![[Case Study of Packaging Design Improvement] Packaging Materials for Overseas Transportation](https://image.mono.ipros.com/public/product/image/e30/2000594341/IPROS45533648365585537839.png?w=280&h=280)

![[Research Material] Global Market for Paper and Board Containers and Packaging](https://image.mono.ipros.com/public/product/image/33d/2001463614/IPROS97075029207975872759.jpeg?w=280&h=280)

![Stretch Film "Komaki" [Industry First! Optimal for ECO and Work Efficiency!]](https://image.mono.ipros.com/public/product/image/474/2000317425/IPROS17167699807860247107.jpeg?w=280&h=280)