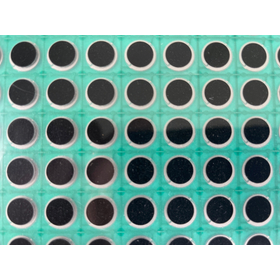

It is a sheet-type pressure-sensitive sensor. It can sense the pressure distribution across the entire surface. Customization to meet customer specifications is also possible.

We have developed an ultra-thin load sensor of a film laminated type that detects changes in electrical resistance based on the magnitude of the load applied to the pressure-sensitive area. Due to its PET film laminated structure, the sensor is ultra-thin (around 0.5 mm) and offers resistance value output. We can accommodate prototype to mass production based on your desired size, shape, performance, surface processing, and printed design according to your applications and purposes. It is also possible to provide a kit for a "buzzer sound and LED lighting unit" that can be used independently, as well as devices that wirelessly transmit sensing output via Bluetooth. The sensor can detect the degree of load or impact at various points and surfaces. 【Features】 - We can accommodate prototype to mass production based on your desired size, shape, performance, surface processing, and printed design according to your applications and purposes. - Specifications can be modified to detect loads above a specified threshold (for surface application). - Waterproof and dirt-resistant products are also available. *For more details, please refer to the PDF document or feel free to contact us.

Inquire About This Product

basic information

For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

【Purpose】 ■ Measurement of pressure distribution on the squeegee of a printing machine ■ Detection of the cleaning condition of products (Measurement of uniform water pressure across the entire surface) *For more details, please refer to the PDF document or feel free to contact us.

catalog(1)

Download All CatalogsNews about this product(4)

Company information

We will assist in problem-solving and product realization through manufacturing technologies based on high-precision "silk printing technology" using PET film as the substrate, "press processing technology" such as embossing, and "lamination assembly technology" for film, along with research/development technologies and planning/design technologies that respond to customer needs.

![[Developed Product] Weight Sensor](https://image.mono.ipros.com/public/product/image/a30/2000595993/IPROS95171791853046327086.png?w=280&h=280)

![[Developed Product] Slide Sensor - Measuring Type](https://image.mono.ipros.com/public/product/image/a0a/2000596032/IPROS29941612648610294626.png?w=280&h=280)

![[Developed Product] Cushion (Seat) Sensor](https://image.mono.ipros.com/public/product/image/d17/2000596033/IPROS50507983086207639792.png?w=280&h=280)

![[Developed Product] Contact Sensor PETANCO Series](https://image.mono.ipros.com/public/product/image/90f/2000695979/IPROS86864299306444249477.jpeg?w=280&h=280)

![[Developed Product] Contact Sensor PETANCO Series](https://image.mono.ipros.com/public/product/image/61e/2000704324/IPROS19577963467912812777.jpeg?w=280&h=280)