Wear and friction, lubricating oil performance test specimen manufacturing and processing service

We will manufacture and process test pieces in various sizes and shapes!

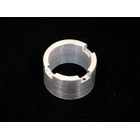

We manufacture and process test specimens for wear and friction tests to evaluate the wear resistance and friction performance of resins and rubber, as well as test specimens for lubricating oil performance tests used in automotive engine oils and metal cutting processes. We can produce friction and wear test specimens and lubricating oil performance test specimens according to JIS standards, ASTM standards, and your company's internal standards. Additionally, we can create test specimens from materials provided by customers. We can manufacture and process test specimens in various sizes and shapes. *For more details, please contact us.*

Inquire About This Product

basic information

We manufacture and process test specimens for standard testing methods such as the pin-on-disk wear test method (ASTM G99 - 17), the ball-on-disk wear test method for fine ceramics (JIS R 1613), the sliding wear test method for plastics (JIS K 7218), the lubricating oil load-carrying capacity test method (JIS K 2519), the standard test method for evaluating the wear resistance of materials against sliding wear using the block-on-ring wear test (ASTM G77 - 17), and the standard test method for wear measurement using a dry sand/rubber wheel apparatus (ASTM G65), among others. We produce test specimens from materials such as steel and stainless steel, non-ferrous metals like copper, and non-metals like resins. The specifications of the test specimens (material, shape, heat treatment, polishing treatment, and various surface treatments) will be determined through consultation. *For more details, please contact us.*

Price range

Delivery Time

Applications/Examples of results

For more details, please contact us.

Detailed information

catalog(1)

Download All CatalogsCompany information

Engineering Test Services (ETS) specializing in the manufacturing, sales, and processing of test specimens! We produce and process test specimens for various tests such as wear and friction tests, lubricant performance tests, rust prevention and corrosion tests, adhesion tests, adhesive tests, material tests, and plating tests from a wide range of materials including steel, stainless steel, and steel plates, non-ferrous metals like aluminum, copper, and magnesium alloys, as well as non-metals like resins, stone and cement products, and rubber. We manufacture and process test specimens according to JIS standards, ASTM standards, and your company's internal standards. We also offer various surface treatments and processing, including blast treatment, electrolytic coloring, polishing, and bending. Furthermore, we can process materials provided by customers and manufacture testing jigs. We manufacture and process test specimens in various sizes and shapes, so please feel free to contact us.