Introduction to Markerless Motion Capture - Measurement Procedure

Markerless motion capture

Markerless motion analysis measurement procedure

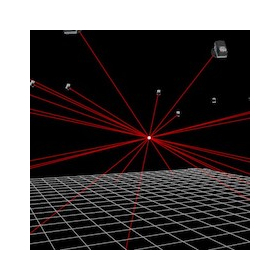

Introducing the measurement procedure for the markerless motion capture Qualisys/THIEA system. The markerless dedicated three-dimensional motion analysis software THEIA3D measures using a unique algorithm from the footage of multiple cameras and calculates skeletal model segment information. By combining it with the Qualisys high-speed camera system and hybrid camera system, it is possible to perform camera setup, calibration, measurement, and analysis all in one go. The video introduces the flow from calibration/measurement/analysis of the markerless motion capture system. [Video] Markerless Motion Capture Tutorial https://www.youtube.com/watch?v=hnDYMxuv1AQ

Inquire About This Product

basic information

□ Markerless measurement □ Support for multiple users □ Skeleton model detection □ Three-dimensional analysis/report output □ Compatibility between Qualisys system and THEIA

Price range

Delivery Time

Applications/Examples of results

□ Markerless motion capture □ Sports performance analysis □ Gait analysis □ Ergonomics □ Rehabilitation

News about this product(1)

Company information

We handle high-precision measurement equipment that can be used for ergonomics, building structure, behavior, seismic analysis, fluid analysis, VR, and more, both domestically and internationally. In particular, the Qualisys system we offer is a leading company in the industry that manufactures a three-dimensional optical motion capture system based in Sweden. Qualisys's core technology has been developed since 1989, and based on years of accumulated experience, they develop everything in-house, from hardware like cameras to software. Currently, motion capture systems are used in a wide variety of fields, including medicine and industry. Among their products, there is a unique model that can measure underwater, enabling the acquisition of high-precision three-dimensional data in environments where motion analysis and validation of accuracy were previously impossible.

![Introduction of Motion Capture User Cases [Animation]](https://image.mono.ipros.com/public/product/image/335/2000680754/IPROS83056935705240833798.png?w=280&h=280)

![[Musculoskeletal Analysis Example] Analysis example for evaluating assist suits (muscle suits)](https://image.mono.ipros.com/public/product/image/860/2000697646/IPROS17079217364044468641.png?w=280&h=280)