Introduction to Tape Processing Technology - Half-Cut Processing and Back Slitting Processing Edition -

We will process various adhesive tapes to meet your needs and desired shapes.

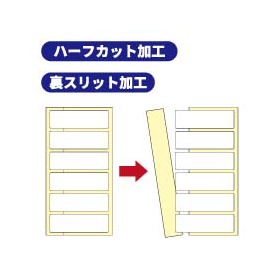

Introducing half-cut processing and back slit processing! 【Half-Cut Processing】 This involves cutting only the main part of the sticker. Cuts are made only in the sticker area while leaving the backing intact. Unwanted parts are raised to make it easier to peel off the sticker portion. Additionally, it is possible to arrange multiple shapes on a single sheet. 【Back Slit Processing】 By adding slits (cuts) to the separator, the sticker portion becomes easier to peel off, leading to improved workability.

Inquire About This Product

basic information

Please consult us with any concerns regarding tape. We will provide the best proposal by combining our tape processing technology.

Price range

Delivery Time

Applications/Examples of results

Tape processing

Detailed information

-

Half-cut processing involves cutting only the main part of the sticker. Cuts are made only in the sticker area while leaving the backing intact. Unwanted parts are removed to make it easier to peel off the sticker. Additionally, it is possible to arrange multiple shapes on one sheet.

-

【Back Slit Processing】 By adding slits (notches) to the separator, the sealing part becomes easier to peel off, leading to improved work efficiency.

catalog(1)

Download All CatalogsCompany information

Logical Eye Co., Ltd. supports manufacturing companies by providing a total solution for packaging materials, labeling materials, logistics equipment, standard component trays, and protective materials. Leveraging over 60 years of experience and achievements from the Suzuka Group, we respond to manufacturing technology with expertise. We think logically and provide answers. That is the mission of Logical Eye. We respond with a sense of speed to requests from various fields such as automotive, housing, housing equipment, textiles, and petrochemicals with technological support.