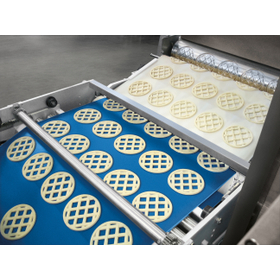

Ensuring profits requires "stabilization of quality" and "improvement of productivity"! To achieve both, a rice robot is an essential piece of equipment!

Here is a case study of the introduction of the "Rice Robot" at a supermarket in Funabashi City, Chiba Prefecture! At that time, we were only able to produce 3 to 4 pots of rice and 150 to 200 bento boxes per day, and we were considering hiring new employees to increase sales. However, after the introduction of the "Rice Robot," we were able to produce 10 to 13 pots of rice and 500 to 700 bento boxes per day without increasing staff. The cost of purchasing the machine was recouped in just two months! 【Case Study】 ■ Product Introduced: Rice Robot ■ Model: KR902A ■ Background of Introduction: Quality improvement, stabilization, productivity enhancement ■ Delivery Date: April 2003 *For more details, please contact us through the [Ipros Urban Development Site] or [Special Site]. *If you are viewing the manufacturing, pharmaceuticals, and food technology site, we kindly ask you to download the catalog from the [Special Site].

Inquire About This Product

basic information

For more details, please refer to the related links or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the related links or feel free to contact us.

Company information

As "rice experts," we provide a higher level of "deliciousness." Through rice, we contribute to the improvement of food culture by considering the future of kitchens and ensuring customer satisfaction.

![[Case Study (Rice Robot)] Bento Manufacturing](https://image.mono.ipros.com/public/product/image/84d/2000667068/IPROS89736762071625224592.png?w=280&h=280)

![[Case Study (RoboChef)] Food Court / Omelette Rice](https://image.mono.ipros.com/public/product/image/c52/2000667099/IPROS26078179093906500932.png?w=280&h=280)