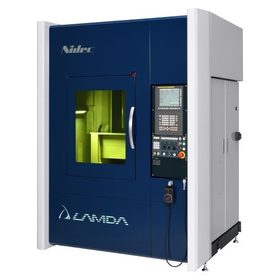

Metal 3D Printer Powder DED Method 3D Metal Additive Manufacturing Machine LAMDA

A 3D metal additive manufacturing device using a powder DED method that also supports large component shaping. For manufacturing parts for automobiles, construction machinery, aircraft, and more!

The features of the metal 3D printer LAMDA series include chamberless operation with local shielding and highly reliable additive manufacturing through monitoring feedback. ■ Local Shielding Laser light is directed onto the material to melt it, creating a localized oxygen-free environment at the tip. This technology enables additive manufacturing of anaerobic materials (such as titanium) even without a chamber. ■ Monitoring Feedback The state during the additive manufacturing process is monitored and fed back into the layering conditions. This allows for clean stacking without distorting the shape.

Inquire About This Product

basic information

For more details, please visit our website. ▼ Powder DED method 3D metal additive manufacturing machine LAMDA https://www.nidec-machinetool.com/product/lamda/ In addition to selling equipment, we also offer services such as prototyping and contract manufacturing. ▼ Metal 3D printer prototyping and manufacturing services https://www.nidec-machinetool.com/product/metal-3d-printing/

Applications/Examples of results

It is suitable for prototyping metal parts, single items, and small lot production, and can be utilized in the following ways: (Examples of applications that leverage features) ■Utilization of near-net shape With the DED method of LAMDA, it is possible to perform build-up on materials with near-net shape (shapes and dimensions close to the final form) and finish them to the product shape. When machining from the outer shape of the product, there is a lot of material to remove, resulting in longer machining times and higher material costs. In contrast, by only building and machining the necessary areas, it is possible to shorten delivery times. Additionally, thinning the material helps reduce costs. ■Efficiency in small lot production of various types In the method of producing casting molds tailored to the final shape, even a slight difference in shape requires a separate mold for each. This leads to longer material delivery times and makes it difficult to accommodate special shapes. When utilizing DED, the basic shape is used as a base to build each flange part. Only the minimum necessary casting molds need to be prepared. If the material has a simple shape, delivery times can be shortened, and it becomes easier to accommodate variations in part shapes.

Line up(3)

| Model number | overview |

|---|---|

| LAMDA200 | Maximum build size 200×200×200mm |

| LAMDA500 | Maximum build size 500×500×500mm |

| LAMDA2000 | Maximum build size 2,000×1,500×1,600mm or 2,500×900×1,000mm |

catalog(1)

Download All CatalogsCompany information

Since our founding in 1939, we have been creating machine tools and cutting tools that are essential to the manufacturing industry. Even as society changes rapidly, we support people's rich lives through "monozukuri" (the art of making things). We constantly pursue new technologies, challenge unknown territories, and continue to provide production systems that are truly needed in the world. This is our commitment.

![[Equipment Introduction] Machining, Heat Treatment, Casting, Inspection Equipment](https://image.mono.ipros.com/public/product/image/be3/2001183933/IPROS70582254147219917554.jpeg?w=280&h=280)

![[Information] Metal Additive Manufacturing - 5 Representative Applications](https://image.mono.ipros.com/public/product/image/34f/2000542983/IPROS84214049895242102336.png?w=280&h=280)

![[Column] Key Points for Estimating 3D Printing Services](https://image.mono.ipros.com/public/product/image/93f/2001455124/IPROS11150412000312378993.png?w=280&h=280)

![Burr Removal Machine "Triple Baritol" [Eligible for Small and Medium Enterprise Labor-Saving Investment Subsidy]](https://image.mono.ipros.com/public/product/image/fbb/2000308526/IPROS10846500360243567721.png?w=280&h=280)

![Deburring Machine "Twin Baritor" [Eligible for Small and Medium Enterprise Productivity Investment Subsidy]](https://image.mono.ipros.com/public/product/image/6d3/2000308654/IPROS16685940644635288329.png?w=280&h=280)