AI automatically detects defects in metal parts and other items using only good products! AI visual inspection is now possible for complex shapes like die-castings, which could only be inspected visually before.

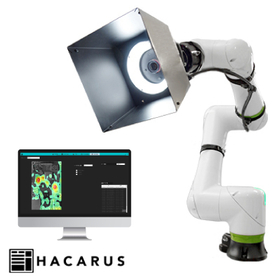

The AI visual inspection system "HACARUS Check" is an all-in-one package that automatically detects defects in workpieces using "collaborative robots + cameras with lighting + high-performance AI." It can be implemented as a one-stop solution from imaging with robots and cameras to AI's OK/NG judgment. With the ability to conduct 360-degree inspections, it is suitable for complex-shaped workpieces such as die-cast and machined products, achieving reductions in inspection labor and standardization of quality. ■ Target Workpieces Small automotive parts, die-casting, metalworking and processing, press processing, plating, bearings, textiles, rubber, resin, plastics, ceramics, etc. ■ Features 1. 360-Degree Inspection The 6-axis robotic arm, illuminated ring lighting, and rotating lift platform work together to detect defects in hard-to-image areas. 2. Small Quantity, Good Quality, Fast Learning AI Thanks to HACARUS's unique AI technology, there is no need to collect defective product data; a high-precision AI can be quickly built from a small amount of good product data. 3. Easy Installation Compact design, operates on 100V power supply. Overall dimensions: 1555mm × 740mm × 860mm (fixed with caster-mounted adjusters). *For more details, please visit the product's special website below.⬇︎

Inquire About This Product

basic information

【Set Contents】 ■Hardware Collaborative robot, camera, lighting, rotating lift platform, robot control, enclosure with emergency stop button, PC ■Software AI inspection software 【Implementation Effects】 ■Significant reduction in inspection man-hours ■Improvement in inspection accuracy ■Inheritance of skilled inspector techniques *For details, please request materials or view the PDF data from the download.

Price range

Delivery Time

Applications/Examples of results

【Target Defects】 Scratches, dents, casting defects, flow lines, uneven paint, dirt, etc. 【Target Workpieces】 Automotive parts, metal products with surface characteristics Examples: die casting, metal working and processing, press processing, plating, bearings, fibers, rubber, resin, plastic, ceramics, etc. *For more details, please refer to the PDF document or feel free to contact us.*

News about this product(8)

Company information

HACARUS is on a mission to build the next generation of tools for those shaping the future with its proprietary AI core - built to provide big insights from small data. Since 2014 it has helped companies solve problems in manufacturing, construction and infrastructure, among other industries. HACARUS is especially good at turning human expertise into digital instruments, to streamline operations and save on labor. By providing a full suite of services, from support of data acquisition to integration with existing systems, the company is committed to create a future where humans and AI coexist.

![[Data] AI Visual Inspection Solution for Shaft Components](https://image.mono.ipros.com/public/product/image/314/2000670092/IPROS68924932930247170090.png?w=280&h=280)