With the introduction of automatic packing machines, we have achieved an 80% reduction in labor costs! While compensating for the decrease in the workforce, we have also increased the number of shipping boxes!

【Are you facing these packaging and shipping issues?】 ■ Struggling to secure personnel ■ Need for further packaging efficiency improvements ahead of the 2024 problem ■ Pressure to reduce costs ■ Being asked to consider environmental concerns ⇒ Leave it to Ranpak's automatic sealing machine 'Cut’it! EVO' 【Features】 ■ High-speed processing ・ Up to 15 boxes per minute ⇒ One of the fastest in the industry! Enables shipping of more boxes ■ Total cost reduction ・ Automation (labor-saving) ⇒ Reduction in labor costs (with a proven reduction of 80%) ・ Optimization of cardboard box sizes ⇒ Reduction in transportation costs ■ Reduction of environmental impact ・ Optimization of box sizes ⇒ Increased number of boxes per truck ⇒ Reduction in the number of trucks, leading to decreased exhaust emissions ■ Small installation space ・ Suitable not only for new installations but also for replacing existing systems! We have catalogs and case studies available. Please feel free to contact us.

Inquire About This Product

basic information

【Simple Steps】 1. Arrange the products in the cardboard box. 2. Cut’it! EVO detects the highest point of the contents and automatically cuts the four corners of the cardboard box. 3. Fold the flaps. 4. Place a lid over the folded flaps and glue it. We have catalogs and case studies available. Please feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

It is ideal for the following industries: ■ Consumer goods ■ Beauty and healthcare ■ Office supplies ■ Graphic arts ■ Electrical/Electronic equipment ■ Tools and machinery, etc.

Line up(4)

| Model number | overview |

|---|---|

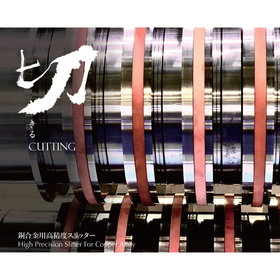

| Cut'it! (TM) EVO | A sealing system with height adjustment function. Automatically adjusts the height of the box according to the height of the contents inside, and attaches the lid. Reduces unnecessary gaps inside the box, lowering both shipping costs and environmental impact. |

| Flap'it (TM) | An automatic packaging solution ideal for packing small-sized products such as books and photos. Generates boxes by twisting cardboard, eliminating the need for a box-making machine. |

| Form’it! (TM)Tray | Easy tray forming with an automatic box-making machine! Reduces labor, increases productivity, and eliminates the need for accumulation. With a small footprint, integration into existing packaging lines is also simple! |

| Form’it! (TM) Case | Easy carton forming with an automatic box-making machine! Reduces labor, increases productivity, and eliminates the need for accumulation. With a small footprint, integration into existing packaging lines is also simple! |

News about this product(1)

Company information

Rampack Co., Ltd. provides sustainable solutions using paper cushioning materials for product protection during transportation. While many companies handle both "paper" and "plastic" materials, Rampack has specialized exclusively in "paper" for the past 50 years, accumulating expertise in this area. In the field of cushioning and packaging, measures for environmental consideration, such as reducing plastic, are becoming essential. We support initiatives towards the SDGs with our eco-friendly "paper" solutions. Additionally, we respond to customer requests for improvements, such as reducing damage risks and increasing packaging speed! In addition to "paper cushioning materials," we also offer "automation solutions" such as automatic cardboard forming machines and sealing machines with height adjustment functions. We encourage you to consider these for further productivity improvements and addressing the declining labor force. Through proposals for process improvements, Rampack contributes to enhancing our customers' production efficiency and reducing total costs.