Glossy paint, piano black paint, UV paint, resin paint, metal paint, etc.

Leave high-difficulty coatings such as glossy paint, piano black paint, and pearl paint to us.

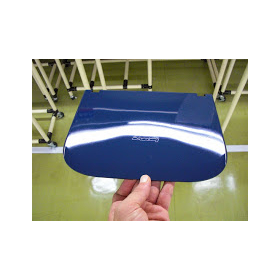

We provide technical support for high-difficulty painting of resin and metal products, from prototyping to mass production, addressing various requests related to painting. The photo shows the painting of a laptop series. We can accommodate small lot sizes. We offer urethane painting and UV painting, and we perform painting for design surfaces in automotive, medical, and robotics applications. We can undertake a consistent process from mold making, molding, to secondary processing. Additionally, we conduct various evaluation tests based on JIS standards, including printing and ultrasonic welding. We accommodate small lot sizes. Types of evaluation tests: 1. Light resistance test... applicable to automotive and robotics painting 2. Acid resistance and alkali resistance tests 3. Abrasion resistance test 4. Temperature and humidity tests, etc. Related URL: http://swifttechnoligy.seesaa.net/

Inquire About This Product

basic information

The paint used in coating processes is mainly composed of the following five components: Resin: A component that affects the performance of the coating film and its durability. Hardener: A component that reacts with the resin to improve the strength of the coating film. Pigment: A component that influences coloring, rust prevention, and strength. Additive: A component that affects the viscosity and workability of the paint. Solvent: A component that dissolves the resin and hardener to create a uniform coating film. The differences in these paint components allow for the classification of coatings.

Price information

Please consult with us.

Delivery Time

Applications/Examples of results

Automotive parts, medical device parts, robot parts, etc., exterior painting and decorative surface painting.

catalog(1)

Download All CatalogsCompany information

Our company is a fabless manufacturer without a factory. We have established a strong network with local companies in Kunshan, Shanghai, China. Since we have an office in Japan, we can hold technical meetings with customers in Japan without the need for business trips to China. Our office allows for smooth communication with local companies through remote instructions and reports. The strengths of Chinese mold manufacturing are power and speed. In Japan, there are many small businesses, making it difficult to respond to short delivery times. Additionally, while the yen is trending weaker, China still remains advantageous in terms of pricing. The issue is quality, but our local office staff provides meticulous support, and there have been no major troubles to date. Furthermore, we conduct quality checks at our Japan office as needed, ensuring a reliable system for our customers. We are confident that we can fully meet our customers' demands for short delivery times, high quality, and low prices. Contact Information: Japan: 027-347-1738, 090-6159-0808 (Hamada) China: 13915749671 (Dang Lina: Japanese/Chinese) Japan Office: 1102-4 Kuragano-cho, Takasaki City, Gunma Prefecture Inside Takasaki Monozukuri Technology Research Institute LLC

![[Proposed Solution Example] Improvement of Slipperiness of Inkjet Printer Nozzles](https://image.mono.ipros.com/public/product/image/9a2/2000650501/IPROS08191313331350301345.png?w=280&h=280)