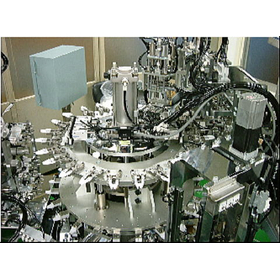

Design and manufacture automatic assembly machines tailored to customer product configurations and the presence or absence of safety features.

We manufacture "needle assembly machines" tailored to our customers' needs. The equipment is configured with necessary and sufficient inspection units for outer needle tip shapes, inner and outer needle assembly, and inner needle blade tip damage. It is also capable of automatic feeding into blister packaging machines, as well as individual packaging and small box feeding through pillow packaging. Please feel free to contact us when you need assistance. 【Features】 ■ The material for outer needles includes PVC, PP, as well as proven tip molding with Teflon and urethane. ■ Side hole drilling through punch processing is also implemented. ■ Equipped with necessary and sufficient inspection units for outer needle tip shapes, inner and outer needle assembly, and inner needle blade tip damage. ■ Capable of automatic feeding into blister packaging machines and individual packaging and small box feeding through pillow packaging. *For more details, please refer to the related links or feel free to contact us.

Inquire About This Product

basic information

[Related Equipment] ■ Side hole indwelling needle processing machine ■ Enema assembly machine ■ Guide wire inspection/bagging machine ■ Suction catheter processing machine *For more details, please refer to the related links or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the related links or feel free to contact us.

Company information

Since our founding, we have valued each and every job, keeping in mind the construction of equipment that meets our customers' needs, and we have diligently walked this path for over 40 years. Our machines are not only exported within Japan but also to countries such as China, Malaysia, Brazil, Thailand, and India, and we take pride in having contributed, albeit modestly, to the technological revolution and productivity improvements in those countries. In particular, we have accumulated numerous achievements and refined our foundational technology in the assembly of difficult-to-handle parts such as tubes and rubber products, as well as in large lines exceeding hundreds of millions. We will continue to remember that our encounters with customers are the nourishment for our company's growth, and we are determined to develop the potentially huge markets of China and India, working together as one team to ensure that our technology and quality gain recognition worldwide.

![[Case Study of Custom Machine Manufacturing] Assembly Machine](https://image.mono.ipros.com/public/product/image/83f/2001158557/IPROS03826872019651790886.png?w=280&h=280)