Production time is as short as 1 to 3 days, no molds required, and suitable for complex structures.

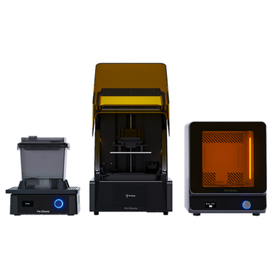

3D printing, or additive manufacturing (AM), is one of various processes for creating three-dimensional objects of almost any shape from 3D models and other electronic data sources, primarily using an additive process that layers materials continuously under computer control. At RPWORLD, SLS (Selective Laser Sintering), SLA (Stereolithography), and FDM (Fused Deposition Modeling) are used as the most common additive manufacturing processes to realize projects. Additive manufacturing is designed for functional prototypes, complex designs, and production parts.

Inquire About This Product

basic information

Light Shaping A layered manufacturing technology that hardens light-reactive resin using ultraviolet lasers and creates models, prototypes, patterns, and production parts layer by layer, also known as 3D printing technology. Laser Sintering A layered manufacturing technology that uses a laser as a power source to sinter powder materials (usually metals or polymers). It automatically directs the laser to points in the space defined by a 3D model, bonding the materials to create solid structures. It is similar to DMLS (Direct Metal Laser Sintering). Laser Melting A rapid prototyping technology that uses metal powder to directly manufacture metal parts with high density and excellent mechanical properties.

Price range

Delivery Time

Applications/Examples of results

Precision The latest 3D printing technology allows for accommodating tighter tolerances. Durability SLS nylon is a highly durable material with excellent impact strength, flexibility, and environmental resistance. Scalability SLS can easily produce one part or component just as easily as dozens of production pieces. Complex Shapes The 3D printing process allows for easier construction of shapes, enabling the addition of complex geometries without incurring extra costs. Rapid Turnaround Generally, parts are shipped within 3 to 5 days, which shortens lead times and reduces time to market. For information on implementation results, please feel free to contact us.

Company information

Our company was established in 2003 and has developed into a globally renowned provider of low-volume, high-variety production services. Through over a decade of rapid and steady growth, we have become one of the world's fastest digital manufacturers for rapid prototyping, low-volume production, and on-demand production. Moving forward, based on the principle of "Under Promise Over Deliver," we will increase our investment in research and development, cultivate a high-quality talent team, provide strong technical support for the company's sustainable, healthy, and rapid development, and offer our customers faster and better services.