【Case studies now available!】NC machining handled by a non-ferrous materials wholesaler.

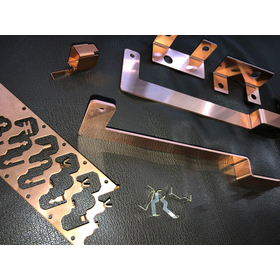

Numerous mass production achievements for hydraulic, pneumatic, and gas equipment! Cost advantages and processing results made possible by Tatsumiya Metal, which has the dual identity of a materials trading company and a machining manufacturer!

Tatsumiya Metal has two faces: "a non-ferrous materials wholesaler with over 80 years of history" and "a machining manufacturer with over 30 years of experience," leveraging each function to enable cost advantages and stable supply. Equipped with 46 NC multi-tasking lathes, roundness measuring instruments, and shape measuring machines, we have established a system that can meet high standards of quality. We have numerous mass production achievements for major domestic pneumatic valve manufacturers and hydraulic equipment manufacturers, earning us a high level of trust. Additionally, we have processing achievements for lead-free brass materials compliant with RoHS2 (Mitsubishi Material Corporation's Eco Brass and San-Etsu Metal Co., Ltd.'s BZ-5), enabling us to provide integrated support from procurement to processing. *If you find yourself saying, "I can process it, but I can't get the materials..." please contact Tatsumiya Metal!

Inquire About This Product

basic information

"Main Achievements in Correspondence" [Materials] Brass: C3602, C3604, C3771 (also capable of handling cadmium-free materials) Lead-free brass: Eco Brass (Mitsubishi Material), BZ-5 (San-Etsu Metal) Bronze: CAC406 Aluminum: A2017, A5052 Stainless steel: SUS303, SUS304, SUS316, SUS316L Iron: S45C, SGD3M, SUM23, SUM23ML, SF20T, SCM415 Others: Chrome copper, tellurium copper, titanium [Client Industries] Gas equipment, hydraulic construction machinery, pneumatic equipment, electronic devices, automobiles, etc. *For more details, please download the catalog or contact us.

Price range

Delivery Time

Applications/Examples of results

[Delivery Performance] Automobiles, hydraulic control, pneumatic control, aerospace, medical, city gas, LP gas, semiconductors, low voltage, solar power generation, and others.

catalog(10)

Download All Catalogs

![Case Studies of Precision Machined Parts [A Cutting Manufacturer with In-Depth Knowledge of Materials - Tatsumiya Metal]](https://image.mono.ipros.com/public/catalog/image_generated/01/266/350929/350929_IPROS1113235389997356725_1.jpg?w=120&h=170)

Company information

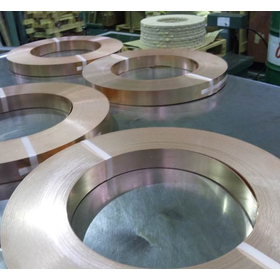

<Metal Materials Trading Division> With a rich inventory and four slitting facilities, we supply from the Higashi-Osaka Coil Center to the entire country. We specialize in the sales of copper alloy materials and non-ferrous metal materials. We are also actively proposing the next-generation copper-aluminum clad material "CCAC" in collaboration with Applied Composite Material Corp. <Metal Processing Division> We excel in processing small quantities of various metal pipes. Our diverse technologies include coil winding, R-bending, various bending processes, and welding. We handle everything from one-off parts used in heat exchanger components and machinery to larger quantities for automotive, consumer, and housing equipment. In the world of bending processing, where small lots are common, the presence or absence of molds becomes quite important. We mix our own molds and equipment with those from partner factories to provide tailored proposals. Additionally, our NC automatic lathe precision cutting processing leverages the procurement advantages unique to Tatsumiya, which has a metal materials trading division, enhancing customer satisfaction through technical expertise, procurement capabilities, and cost efficiency. With over 90 years of establishment as a processing trading company, we view the 100-year mark as a milestone and will continue to build a great company in the future.

![Check the trends of the copper bullion market at a glance! Analysis! [Free graph available]](https://image.mono.ipros.com/public/product/image/9a9/2000242416/IPROS2235627367216692879.png?w=280&h=280)

![[Product Introduction Video] Product Video 1 | Fujino Metal Co., Ltd.](https://image.mono.ipros.com/public/product/image/b1d/2000859980/IPROS11638846806605969810.jpeg?w=280&h=280)