It is possible to reduce the cost of consumable parts and maintenance! A device that takes up relatively little space.

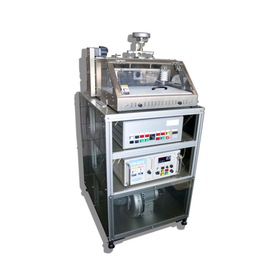

The "cylindrical rotary drum type single-liquid lubrication treatment device" is a product suitable for processing a relatively small quantity of workpieces rather than large volumes. The structure is simple. It features a rotary drum that resembles a hollowed-out cylindrical tube, stored within a booth. Inside the rotary drum, spiral blades are installed, and as the rotary drum rotates, the inserted workpieces move towards the exit. 【Features】 ■ Very little steam or odor leaks to the outside ■ Advantages in the running costs of chemicals ■ The amount of heat required for heating is relatively low, allowing for energy cost reduction ■ Due to its simple structure, it has a low failure rate and excellent maintenance characteristics ■ Possible to reduce costs for consumable parts and maintenance *For more details, please refer to the PDF document or feel free to contact us.

Inquire About This Product

basic information

For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

catalog(1)

Download All CatalogsCompany information

Since our establishment in October 1971, we have been dedicated solely to metal surface treatment equipment. "Providing satisfaction to our customers" is the foundation of all our thinking as we deliver various types of equipment. In 1977, we developed a lubrication treatment device for cold forging that is completely different from conventional methods, using a rotary drum system, and we obtained a patent for it in September 1988. This device not only meets the needs of the times with energy-saving, pollution reduction, and labor-saving (inline integration) features, but it is also highly superior in terms of environmental considerations. Thanks to this, we have received great acclaim since its initial delivery and have built a wealth of achievements. In October 1990, we exported it to the United States, where it has garnered attention not only domestically but also in various other countries. Our wish is to be of service to our customers through our equipment.

![Bonding processing equipment [Achieving automation of the line]](https://image.mono.ipros.com/public/product/image/b40/2000258933/IPROS8416257476550679381.jpg?w=280&h=280)

![[Medical Device] Atmospheric Pressure Plasma Device Application Example (2)](https://image.mono.ipros.com/public/product/image/b8b/2000538558/IPROS17409023974452147010.jpeg?w=280&h=280)