Terminal insertion is supported by mold structure! We will introduce our achievements in producing high-precision molds based on our company's track record!

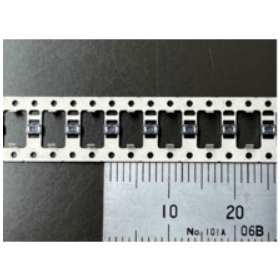

We would like to introduce the design and manufacturing achievements of plastic molds conducted by Alpec. This case involves a fine product with no terminal guiding shape, and the product tolerances are strict. Several companies declined to manufacture the mold, and it came to us through a client referral. Therefore, we manufactured a high-precision mold based on our track record. The terminal insertion was handled by the mold structure. As a result, terminal insertion was smooth, and mass production molding was carried out without any issues. In addition, we have achievements in manufacturing the lid of the above-mentioned component (case) as a set, as well as semiconductor components where we ensured fluidity by innovating the shapes of runners and gates. 【Overview of Achievements (Partial)】 ■Material: LCP ■Size: 1.5×2.4×0.5 ■Application: Electronic components *For more details, please refer to the PDF document or feel free to contact us.

Inquire About This Product

basic information

【Other Achievements Overview】 ■Material: LCP ■Size: 1.5×2.4×0.7 ■Application: Electronic components *For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

catalog(3)

Download All CatalogsNews about this product(1)

Company information

Alpec Co., Ltd. was founded as a press mold manufacturing company and has transitioned to plastic molds alongside the advancement of resin use across various industries. We leverage our experience in press molds to process composite component molds that combine metal and resin, which have been increasingly in demand recently, and provide products that meet our customers' needs. Please feel free to contact us first.

![[Design and Manufacturing Achievements of Plastic Molds] PBT・PP](https://image.mono.ipros.com/public/product/image/ced/2000778223/IPROS18322796126889289644.png?w=280&h=280)

![[Cleaning Example] 8-piece In-Cabinet](https://image.mono.ipros.com/public/product/image/f87/2000883603/IPROS25598901416146896082.png?w=280&h=280)