Higher durability compared to biodegradable plastics! A material that replaces plastics made from plant fibers!

"Biocomposite-Injection modo-cell" is a sustainable material primarily made from plant fibers (cellulose). It can be used for an extended period under a wide range of environmental conditions as a biodegradable plastic. It is composed of materials made from plant fibers (cellulose), starch, plant-derived natural resins, and water, and is biodegradable in environments where natural microorganisms are present. In a composting environment, it decomposes in about three months*, and in natural environments, it decomposes in the same cycle as trees, contributing to resource circulation. *Based on the European composting standard EN13432. 【Features】 ■ Material primarily made from plant fibers (cellulose) ■ Biodegradable in environments with natural microorganisms ■ Higher durability compared to conventional biodegradable plastics *modo-cell is a registered trademark of Amicaterra Co., Ltd., which holds the patent rights. *Our company has formed a business partnership with Amicaterra and produces and sells various molded products. *For more details, please refer to the related link page or feel free to contact us.

Inquire About This Product

basic information

【Other Features】 ■Heat resistance temperature: -20 to 120°C, water-resistant ■Service life: 2 to 3 years (varies depending on usage and environment) *For more details, please refer to the related link page or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the related link page or feel free to contact us.

Company information

NISSHA has continuously expanded its core technologies by integrating printing technology, which it has cultivated since its founding, with elements such as coating, molding, and metal processing. This has enabled the diversification of products and target markets, as well as entry into global markets, thereby achieving an expansion of its business domain. The current core technologies consist of "printing," "coating," "lamination," "molding," "patterning," and "metal processing," and they continue to evolve and expand by incorporating new technologies and materials.

![[New Hardware] Solar Panel Bird Damage Prevention Fence 'Bird Blocker'](https://image.mono.ipros.com/public/product/image/f07/2000470546/IPROS69097032718359962148.jpeg?w=280&h=280)

![[Purchase] Used pallets and logistics materials](https://image.mono.ipros.com/public/product/image/ec5/2000627219/IPROS56560722479940768821.png?w=280&h=280)

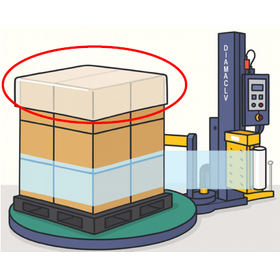

![Stretch Film "Komaki" [Industry First! Optimal for ECO and Work Efficiency!]](https://image.mono.ipros.com/public/product/image/474/2000317425/IPROS17167699807860247107.jpeg?w=280&h=280)