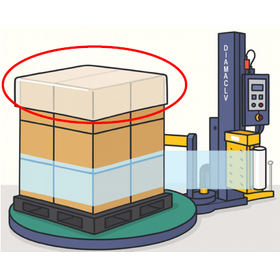

Capable of handling super heavy weights! All processes produced in-house! Reliable quality! Reduced environmental impact! SDGs compliant! Using reinforced cardboard "Naviace"!

【Usage Examples】 - Pumps - Engines - Transmissions - Motors - Inverters - Compressors - Machine parts - Electrical components Packaging for heavy products such as these! 【Main Improvements】 ■ Transitioning to all cardboard from other materials such as wooden boxes, plywood cases, wooden fumigation pallets, wooden beams, composite resin plastic pallets, and steel cases (to address wood shock and reduce plastic usage) ■ Improvement of environmental issues (carbon neutrality, Scope 3, decarbonization, CO2 reduction, etc.) ■ Reduction of cubic meters (improvement of logistics transportation, storage efficiency, resolution of export container shortages) ■ Packaging and unpacking possible by anyone (improvement of work efficiency, productivity, and disposability, etc.) ■ Enhancement of corporate image (ESG investment measures, CSR measures, compliance with Scope 3) *For more details, please refer to the PDF document or feel free to contact us!

Inquire About This Product

basic information

【For those who are troubled by such matters】 - Do not want to use wood or plastic - Want to improve packaging and unpacking efficiency - Want to eliminate waste in delivery and reduce costs - Want to differentiate from competitors - Want to engage in SDGs - Have previously failed in converting to all cardboard - Want to start addressing Scope 3 【Delivery Area】 Kanto region - Tokyo, Saitama, Kanagawa, Chiba, Ibaraki, Tochigi, Gunma (Disaster prevention supplies are available nationwide) 【Factory Location】 Soka City, Saitama Prefecture ● Considering production efficiency and delivery efficiency, single-item processing may lead to increased costs. If you can consider a consolidated quantity (30 units or more), it will be easier to present benefits. ● Molds may be required for production. *For more details, please refer to the PDF document or feel free to contact us!

Price range

P1

Delivery Time

P4

※Since it is completely custom-made, it varies depending on the specifications.

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

catalog(14)

Download All Catalogs

![[Case Study] Reduced CO2 emissions by 8.7 tons with the Navi Palette! A carbon-neutral proposal case. Converting plastic pallets to cardboard pallets.](https://image.mono.ipros.com/public/catalog/image/01/ccc/649818/IPROS84212184234313535782.jpeg?w=120&h=170)

![[Wood Shock Response] Four-way entry electric fork-compatible high-strength cardboard pallet (Navi Pallet)](https://image.mono.ipros.com/public/catalog/image/01/2cc/646579/IPROS23581856870934965326.jpeg?w=120&h=170)

Company information

◆Reinforced cardboard "Navi Ace" ◆Cardboard pallet "Navi Palette" We propose solutions to improve logistics challenges. 【Features】 ~90% of the raw materials are recycled paper~ - Lower CO2 emissions compared to other materials - Higher recyclability than other materials This contributes to carbon neutrality. ~Can be processed using the same methods as regular cardboard~ - Superior processability compared to other materials This allows for custom designs tailored to the contents, thereby improving logistics efficiency and contributing to cost reductions such as transportation expenses. *Other materials = wood, iron and steel, plastic resin, paper tubes, etc. Additionally, we established and relocated our manufacturing base in 2023, expanding our production scale. - Smoother deliveries across the Kanto region - Enhanced quality with new equipment - Production facilities that consider both the global environment and labor conditions - Doubling production capacity allows for the creation of packaging for heavier and more complex products. *As of September 2023, we changed our company name from Fukuno Cardboard Industry to Navi Ace Kanto.

![Stretch Film "Komaki" [Industry First! Optimal for ECO and Work Efficiency!]](https://image.mono.ipros.com/public/product/image/474/2000317425/IPROS17167699807860247107.jpeg?w=280&h=280)