Case studies on solving insert nut press-fitting issues *Case study collection available!

We will introduce a case that solved the issue of wanting to shorten the time required for the pressing operation!

Recently, the number of resin products has been steadily increasing. When producing resin products, various issues need to be considered, and we often receive challenges related to the heat insertion of insert nuts. This time, as we launched a new product, we addressed the customer's request to improve productivity due to the time-consuming process of inserting insert nuts. [Proposal] The conventional manual operation took 77 seconds per workpiece, so we proposed a manual simultaneous insertion machine that reduces the working time to about 35 seconds for four locations. [Result] Typically, two people were needed to handle mass production with the conventional soldering method, but with simultaneous insertion, one person can manage it. As a result, once the day's work is completed, the insertion machine can be easily moved to the edge of the desk or a shelf. Currently, we are producing 10,000 units per month, but due to the reduction in insertion work time per unit, we can now increase production to 16,500 units within the working hours. *For more details, please refer to the PDF or contact us.

Inquire About This Product

basic information

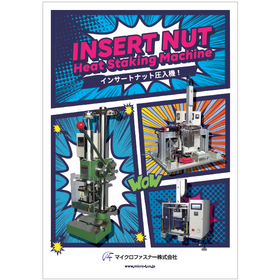

【Benefits of Introducing Insert Nut Pressing Machine】 ■ Multiple insert nut pressing tasks can be completed at once ■ Rapid recovery of installation costs due to overwhelming cost reduction effects ■ Consistent quality regardless of who performs the work ■ No concern about the product becoming defective if one location fails ■ No worries about arm fatigue or tendonitis ■ All kinds of customization are possible, including different pressing heights and sizes, as well as simultaneous pressing at more than ten locations

Price range

Delivery Time

Applications/Examples of results

Insertion of insert nuts.

catalog(1)

Download All CatalogsCompany information

Our company has extensive knowledge and experience in heat press-in processing (outsert processing) for insert nuts in resin molded products. "Outsert quality is unstable." "I want to shorten the delivery time for the outsert process." "I want to review costs." "I want to allocate personnel to core business." "I want to solve issues related to resin leakage and resin burrs caused by outsert processing." "I would like to consult on hole design." "I would like you to design insert nuts." Do you have any such concerns? Based on our rich experience and track record, we provide stable supply of high-quality outsert processing. With our unique know-how and efficient production system, we strongly support the realization of the quality, delivery time, and cost that our customers require. We can flexibly respond from prototypes to mass production. We will not just perform tasks but will provide optimal proposals tailored to your product specifications and production plans. Please feel free to contact us for any technical inquiries regarding outsert processing and insert nuts. For concerns about outsert processing and insert nuts, turn to Prostech. We will robustly support your manufacturing from the downstream processes.

![[For efficient water drainage] 100% water-draining air nozzle](https://image.mono.ipros.com/public/product/image/00f/2001469742/IPROS9319730289540870960.png?w=280&h=280)