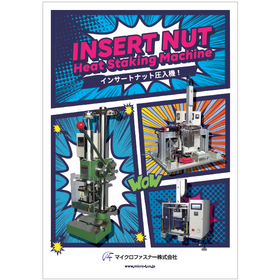

Case study on solving issues with insert nut pressing in semi-automation *Case study collection available!

We will introduce a case that solved the issue of reducing quality variation due to human factors in the press-fitting of insert nuts!

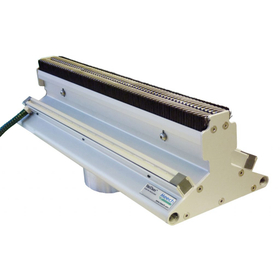

Recently, the number of resin products has been increasing rapidly. When producing resin products, various issues need to be considered, and we often receive challenges related to insert nut heat press fitting. This time, we received a request to stabilize quality because there was a significant variation in the quality of the press-fitting work for off-the-shelf insert nuts, resulting in about 3% defective products. **Proposal** Since defective products lead to wasted time and costs for parts, we proposed a semi-automatic press-fitting machine that can press four units simultaneously, reducing the time humans are involved as much as possible. **Result** The manual part involves setting the insert nut onto the workpiece and moving the stage to the press-fitting position. By automating the "descend → press-fit → ascend" of the heating element, we eliminated the possibility of inadvertently continuing to apply pressure after the press-fitting was completed. This reduced the burden on the resin workpiece and ensured uniform press-fitting times, resulting in no defective products, which was greatly appreciated. *For more details, please refer to the PDF or contact us.*

Inquire About This Product

basic information

【Benefits of Introducing Insert Nut Pressing Machine】 ■ The pressing work for multiple insert nuts can be completed at once. ■ Rapid recovery of installation costs due to overwhelming cost reduction effects. ■ Consistent quality regardless of who performs the work. ■ No worries about the product becoming defective if one location fails. ■ No concerns about arm fatigue or tendonitis. ■ All kinds of customization are possible, including different pressing heights and sizes, as well as simultaneous pressing of more than ten locations.

Price range

Delivery Time

Applications/Examples of results

Insertion of insert nuts.

catalog(1)

Download All CatalogsCompany information

Our company has extensive knowledge and experience in heat press-in processing (outsert processing) for insert nuts in resin molded products. "Outsert quality is unstable." "I want to shorten the delivery time for the outsert process." "I want to review costs." "I want to allocate personnel to core business." "I want to solve issues related to resin leakage and resin burrs caused by outsert processing." "I would like to consult on hole design." "I would like you to design insert nuts." Do you have any such concerns? Based on our rich experience and track record, we provide stable supply of high-quality outsert processing. With our unique know-how and efficient production system, we strongly support the realization of the quality, delivery time, and cost that our customers require. We can flexibly respond from prototypes to mass production. We will not just perform tasks but will provide optimal proposals tailored to your product specifications and production plans. Please feel free to contact us for any technical inquiries regarding outsert processing and insert nuts. For concerns about outsert processing and insert nuts, turn to Prostech. We will robustly support your manufacturing from the downstream processes.