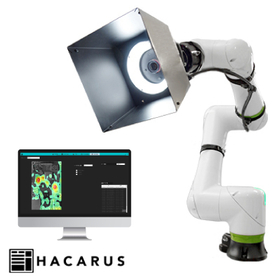

The first AI visual inspection compatible with FANUC collaborative robots: An AI visual inspection solution that automates the visual inspection of complex-shaped automotive metal parts and more.

New Release on June 23: 'HACARUS Check for FANUC CRX Series' This is the first AI visual inspection solution compatible with the FANUC collaborative robot CRX series, achieving complete automation of inspections. To celebrate the launch, we will hold a special price introduction campaign for the first two companies from August 1 to September 30, 2023. There are conditions for applying the campaign, such as the possibility of publicizing case studies, so please contact us for more details. (*The campaign has ended.) ■ Product Features By integrating the FANUC CRX series with the HACARUS Check AI software, which specializes in small quantities, high-quality, and rapid learning, we have made it possible for companies to handle a diverse range of products in small quantities on their own. Additionally, there are no restrictions on the weight or size of the workpieces, similar to HACARUS Check. The solution offers high versatility in the field, and there are no additional development costs. We also provide options for those looking to reduce initial setup costs from the complete automation package for visual inspections. Customization consultations are available based on inspection challenges and environmental conditions.

Inquire About This Product

basic information

- The hardware such as cameras and lighting will be selected by Hakaru based on the target work and inspection environment. - The software can be used immediately after installation from a USB drive. Programming can be easily done by anyone using the dedicated FANUC tablet TP (Teaching Pendant). ■Product Details 1. 360° Fully Automated Inspection Solution Model: CFCD-1000 For those who want to fully automate 360° appearance inspection. It uses two robots: one for inspection and one for transportation and unloading. Hakaru will handle all setup, including robot operations. <Inspection Steps> - The transportation and unloading robot places and flips the parts. - The inspection robot captures images of the parts and inputs them into the AI software. - The AI software determines whether the parts are OK or NG (not good). - The transportation and unloading robot sorts the OK and NG parts and moves them to designated locations. We also have other lineups available. Please feel free to contact us.

Price range

P7

Delivery Time

Applications/Examples of results

Visual inspection of automotive parts, etc.

News about this product(7)

Company information

HACARUS is on a mission to build the next generation of tools for those shaping the future with its proprietary AI core - built to provide big insights from small data. Since 2014 it has helped companies solve problems in manufacturing, construction and infrastructure, among other industries. HACARUS is especially good at turning human expertise into digital instruments, to streamline operations and save on labor. By providing a full suite of services, from support of data acquisition to integration with existing systems, the company is committed to create a future where humans and AI coexist.

![[Information] AI Visual Inspection Solution for Press Gear Components](https://image.mono.ipros.com/public/product/image/95c/2000670063/IPROS13535537839698093896.png?w=280&h=280)

![[Information] AI Visual Inspection Solution for Automotive Motor Parts](https://image.mono.ipros.com/public/product/image/abf/2000670104/IPROS58515730426494487389.png?w=280&h=280)

![[AI Image Inspection Case] Bolt Tightening Strength Inspection](https://image.mono.ipros.com/public/product/image/ffd/2001489585/IPROS1520716176451053411.png?w=280&h=280)