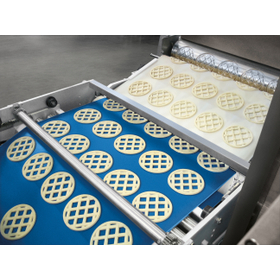

Application of Elea's PEF System in Vegetable Chips Production

Elea's "PEF Advantage B 1" system

The potential of food is unleashed by the perforation of cell membranes caused by PEF (pulsed electric field) treatment.

[Advantages of PEF Treatment in Vegetable Chips Production] Energy and water savings Improved frying management Better seasoning adhesion Significant reduction of acrylamide in PEF-treated vegetable chips Up to 50% reduction in cutting force due to PEF (easier cutting) Creation of new product (shape) opportunities Much longer knife durability Reduction of starch loss due to improved cutting Increased capacity in batch frying Reduction of oil content Improved texture and crispiness Better shape, brighter color, less product breakage

Inquire About This Product

basic information

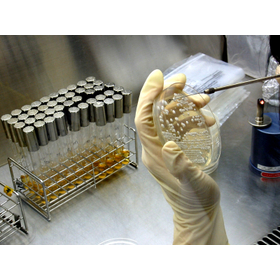

Elea's PEF is a process that creates pores with a diameter of a few nanometers in cell membranes at the cellular level. Elea offers various sizes of the "PEF Advantage" system for different production line capacities. Elea's systems place control in the hands of the operator, allowing for customization of process parameters. With a compact design, the system requires a small footprint for installation, making integration with production lines easy. All systems are designed for 24/7 production and can operate under harsh conditions. For more details, please contact us. We will provide you with detailed materials.

Price range

Delivery Time

Applications/Examples of results

Vegetable chips production

catalog(1)

Download All CatalogsCompany information

Founded in Tokyo in 1948 by German entrepreneur Klaus Koerens, our company was the first German trading company allowed to resume business in Japan after the war. Since our establishment, we have walked alongside Japanese companies through Japan's reconstruction, modernization, and the period of rapid economic growth. Throughout our history of over 75 years, our constant passion has been to introduce cutting-edge technologies from Europe to companies active in various industries in Japan. At the same time, the diverse feedback from our Japanese customers has been reflected back to European suppliers, resulting in many instances of refined technology. We take pride in the fact that we continue to be a leading German trading company in Japan, as this reflects the high regard our efforts have received from both customers and suppliers. Moving forward, we will continue to stand between our Japanese customers and overseas manufacturers, being mindful of differences in business practices, culture, tradition, and behavior, and striving to create better relationships based on mutual respect. Furthermore, we will not only focus on product sales but also make efforts to provide long-term after-sales service to our customers after delivery.