Safety measures through automation: [Automatic Resin Strand Supply System]

WSFO Series (BPM)

Automatically transports strands from the extruder to the pelletizer. In case of strand breakage, it automatically recovers, contributing to safety measures through labor-saving and efficiency improvements.

We would like to introduce the mesh conveyor and water slide system from BPM, which we handle. The resin strands that come out of the die flow down the water slide and are transported by the conveyor. Water is dropped between the water slide and the conveyor. If further cooling is needed, a spray bar can be added to the mesh conveyor. The mesh conveyor removes moisture remaining on the strands through blowing from above and vacuum suction from below. Even if the strands break, the system automatically recovers and feeds them into the pelletizer, reducing manual labor and contributing to safety measures. 【Features】 In new lines of extruders, instead of a water tank, it is possible to: - Control the temperature of the strands - Adjust drying - Recycle water - Filter *For more details, please check the catalog from "PDF Download."

Inquire About This Product

basic information

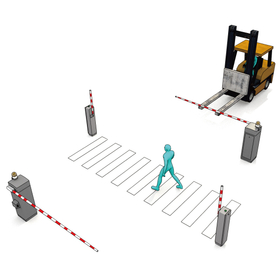

**Wet Cut Water Slide System** The resin strands are transported via the water slide and sent to the feed roll. A spray bar is used to improve cooling. Water is discharged just before the feed roll and is transported within the cutting chamber. The cut pellets fall back into the water, allowing for post-cutting cooling before being transported to the dryer. **Dry Cut Water Slide System** The strands exiting the die flow down the water slide and are carried to the conveyor. Water is dropped between the water slide and the conveyor. If further cooling is needed, a spray bar can be added to the mesh conveyor. On the mesh conveyor, moisture remaining on the strands is removed by a blower from above and vacuum suction from below. Even if the strands break, they automatically return and are fed into the pelletizer.

Price range

Delivery Time

Applications/Examples of results

We recommend the adoption of BPM's automatic strand supply system, which allows for temperature control, drying adjustment, water recycling, and filtering in place of a water tank on the new line of the extruder. In the event of a strand break during operation, it automatically resumes and feeds into the pelletizer. This contributes to automation and labor-saving, as well as reducing downtime.

catalog(1)

Download All CatalogsCompany information

Our company is pursuing wear resistance, corrosion resistance, and heat resistance for various plant equipment and industrial machinery, starting with metal surface hardening. Through the collaboration of our manufacturing division that produces wear-resistant and corrosion-resistant components, our engineering division that designs machine parts and automatic welding machines, and our trading division that utilizes a diverse global network to procure products tailored to customer needs, we aim to be a convenient and valuable company for our customers.