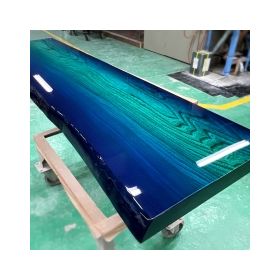

We would like to introduce the gradient mirror finish coating of Zelkova hardwood.

This time, we requested a countertop surface with a scratch-resistant polyester mirror finish. One of the characteristics of polyester resin is that the coating can be made thick, around 0.3 to 0.5 mm. The coating is harder than that of urethane resin, making it less prone to scratches, which makes it suitable for everyday furniture. Additionally, the coating experiences minimal shrinkage over time, and the refined, sharp shine lasts longer, which is another appeal of the polyester mirror finish. Even in the unlikely event that scratches occur, repairs can be made, providing peace of mind.

Inquire About This Product

basic information

For more details, please visit our website at https://www.piax.co.jp/.

Price range

Delivery Time

Applications/Examples of results

For more details, please visit our website at https://www.piax.co.jp/.

Detailed information

-

Blue gradient coloring After completing the "green coloring" → "base coat (4 times on one side)" → "initial sanding," we will apply a blue gradient to the wood base. This is where the craftsman's sense shines. It's a moment of tension!

-

Polyester Clear Topcoat After coloring, a mid-coat (sealer) is applied, and finally, we proceed to the topcoat process. Polyester resin is sprayed on generously and evenly. This is repeated four times as "spray" → "interval" → "spray" ... The finish will vary depending on how the intervals are managed, so experience is necessary to determine the timing based on temperature and humidity.

-

This is a photo of the completed topcoat. A clean base was created with the undercoating, and the topcoat has been applied evenly, so even before polishing, the ceiling's fluorescent lights reflect well, and the gloss is impeccable.

-

Final sanding (level sander) After forced drying, we proceed to the final sanding process. The polyester mirror finish is resistant to scratches and has a hard coating, making machine polishing essential. First, we use a level sander with two stages of sandpaper for the sanding process.

-

Final Polishing (Belt Sander) Next, we will use a belt sander to polish with finer grit sandpaper. Polishing with small machines like hand sanders takes time and can leave rotational scratches, making it difficult to achieve an even finish over a large area. The mirror finish achieved by skillfully modifying and utilizing large, versatile machines from the piano era is what defines the PIAQ quality.

-

Polishing (Automatic Buffing) This is a "three-head automatic buffing machine" that has been used since the piano era. The painted surface is polished to a glossy finish in an instant. It can polish materials up to a maximum size of w1800×d5000×h150.

-

Glossing (Sponge Polisher) After using the "three-head automatic buffing machine," polish the finer details with a cotton polisher, and finally, enhance the gloss with a sponge polisher.

-

Final Confirmation Wipe off the compound, check for any cloudiness, and it's complete. Piax has been dedicated to woodworking finishes for 60 years, with a track record of painting over 80 different types of wood and a vast accumulation of know-how. Wood has its own characteristics, such as deep vessels, high resin content, and oiliness, depending on the species. While manuals may apply to artificial materials (like resin and metal), achieving a beautiful finish on wood requires painting methods and processes tailored to the specific species. Additionally, the amount of moisture contained in the wood affects the penetration of the paint and the quality of the finish, significantly impacting the durability of the coating. In order to provide the highest quality finishes both aesthetically and functionally, we strive to improve our techniques daily, taking into account our clients' requests. Please feel free to contact us for consultations or estimates regarding painting.

catalog(1)

Download All CatalogsCompany information

"Painting Mirror Finish in the Heart of the Piano Industry: Hamamatsu" Hamamatsu City in Shizuoka Prefecture is home to world-renowned piano manufacturers. Our company has established a painting factory in Hamamatsu and has a track record of 30 years in subcontracting painting for both large and small piano manufacturers since our founding. For 60 years since our establishment, we have diligently honed our painting skills. Currently, we utilize our piano painting technology to create custom furniture, store fixtures, interior doors, wall panels, and more, focusing on unique items for brand shops, residences, luxury apartments, and commercial facilities, bringing joy to many customers. We also receive many requests from other specialized painting contractors, particularly for mirror finish painting, where we are trusted with high-volume and complex shapes, as well as projects requiring the highest quality. They say, "We can't handle it ourselves, so if we ask PIAXX, we can trust the quality and delivery!" In the heart of the piano industry, Hamamatsu, we have a "Hamamatsu Monozukuri Meister" certified by the mayor of Hamamatsu. PIAXX's painting technology provides additional value to our customers' products and technologies.

![[Woodworking Coating Example] Indoor Fixtures with Urethane Mirror Finish](https://image.mono.ipros.com/public/product/image/ebc/2000983657/IPROS50375622186857520648.png?w=280&h=280)

![[Leveling Correction] Leveling correction of concrete floors "Teratec Method"](https://image.mono.ipros.com/public/product/image/d08/1267539002/IPROS70063422645318547243.jpeg?w=280&h=280)

![[Case Study] Construction Example of High-Temperature Facilities in Factories Using High-Performance Heat Insulation Sheets](https://image.mono.ipros.com/public/product/image/962/2000579577/IPROS04218491152233419232.jpeg?w=280&h=280)