[Technical Column #15] The Size of Heat Sink Surface Area and Its Heat Dissipation Effect

We will introduce points to consider during design and original technologies to enhance cooling effects through plating!

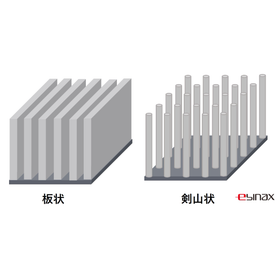

The heat sink's heat dissipation effect varies depending on its surface area. In this column, we will introduce what size of surface area is preferable, as well as the mechanism and necessity of heat dissipation in heat sinks. Additionally, in the latter part of the column, we will present our original technology that enhances cooling effects without changing the base material. For more details, please refer to the related links. [Content Overview (Excerpt)] ■ What is the ideal surface area for heat sinks? ■ Comparison of heat sink shapes and thermal resistance ■ The necessity of heat sinks and the mechanism of heat dissipation ■ Key points for optimizing heat sink design ■ Enhancing heat dissipation effects compactly without increasing surface area *For detailed content of the column, please refer to the related links. For more information, feel free to contact us.

Inquire About This Product

basic information

【Other Published Content】 ■ "Sugohie" that enhances cooling effects through plating ■ Please consult us if you are struggling with the design of heat sink shapes *For detailed content of the column, you can view it through the related links. For more information, please feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

The detailed content of the column can be viewed through the related link. For more information, please feel free to contact us.

Company information

Since its establishment in 1946, the company has continuously refined and innovated its technology development, consistently anticipating the intense changes in the times and markets, while responding to cutting-edge needs in surface treatment. In particular, based on the addition of required functions, the technology and management standards in plating processes, centered on "electroplating" and "electroless plating," which require advanced technology and quality such as adhesion, corrosion resistance, and precision, are recognized as top-level in the industry, earning high evaluation and trust from customers. *The company name was changed from "Ebina Denka Kogyo Co., Ltd." on April 1, 2024.

![[Technical Column #07] Explanation of the Principle of Heat Sinks](https://image.mono.ipros.com/public/product/image/ef1/2000999117/IPROS10938518213854665746.png?w=280&h=280)

![[Technical Column #09] The Mechanism of Heat Sinks](https://image.mono.ipros.com/public/product/image/0e3/2000999124/IPROS32206978026651824055.png?w=280&h=280)