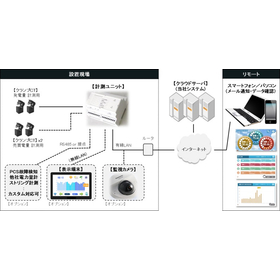

Hydraulic equipment and generator visualization and labor-saving = real-time remote monitoring system.

HYDROTECHNIK UK Ltd. Model: WLPROHSM

Proposal for a package unit equipped with pressure, temperature, flow rate, and oil cleanliness management, featuring ICT remote monitoring in a cloud-based system (WiFi and 4G network).

The Watchlog PRO hydraulic system monitoring unit, equipped with pressure, temperature, flow rate, and oil cleanliness management, can be installed in hydraulic systems to continuously send flow rate, pressure, temperature, and optionally oil cleanliness data to a dedicated cloud via 4G (SIM card) or Wi-Fi, or to your company's web server. The sensor measurements can be displayed and saved on your smartphone using an online cloud platform accessible from most web browsers. Alert options can be configured to notify on-site personnel with buzzers, stack lights, or a combination of both, and it is also possible to send email/SMS messages via the cloud. The Watchlog PRO hydraulic system monitoring unit is powered by AC100V and is installed inline with hydraulic equipment, providing a one-stop solution for remote hydraulic monitoring needs.

Inquire About This Product

basic information

Collection and visualization of hydraulic equipment data! Easy and real-time remote monitoring. Do you have any of the following issues or challenges? ■ Regular visual inspections of pressure gauges and other equipment located in remote or high, dark places are necessary. ■ Regular patrols and inspections are being conducted despite a shortage of personnel. ■ The internal network cannot be used for security reasons. ■ I want to be able to view sensor measurement values on my smartphone at all times. ■ I want to analyze the collected data and use it for failure prediction. ■ There is no network environment nearby, but digitalization is necessary. ■ I want to streamline condition monitoring due to the large number of hydraulic devices. ■ I want to remotely monitor the operating status of hydraulic equipment that operates at night.

Price information

The price varies depending on the combination of sensors.

Delivery Time

※The price may vary depending on the quantity and specifications, so please feel free to contact us.

Applications/Examples of results

Monitoring and Control Items Pressure / Oil Temperature / Flow Rate / Oil Cleanliness (Optional) / Liquid Level (Optional) / GPS / Pitch, Roll, Vibration / Ambient Temperature / Voltage / Various Other Sensors (Please Consult Us) Features It is possible to remotely check the operating status of hydraulic equipment in factories and remote facilities in real-time using a smartphone or PC. With features such as alarm emails/SMS messages, current value display, and regular logs, it contributes to the stable operation of generators and compressors and the efficiency of maintenance work. 4G mobile phone networks are also available, making it compatible with portable equipment, construction machinery, and agricultural machinery. The power supply voltage supports AC 100/200V and DC 24V.

Detailed information

-

Watchlog PRO Cloud Gateway--- The integrated component Watchlog Pro receives all sensor data before sending it to the cloud via WiFi or 4G mobile networks, and optional alert buzzers and stack lights are also triggered by Watchlog Pro.

-

Stainless steel cabinet with external antenna--- This robust cabinet is designed for industrial environments and allows for easy connection to hydraulic units via IN/OUT external ports. The connection pipe diameter for the flow sensor (In/Out) and the overall size of the enclosure vary depending on the model of the flow sensor selected.

-

TE300 Temperature Sensor and PR130 Pressure Sensor--- Temperature Sensor: -50 to 200℃, Accuracy: 0.1% (F.S.), Pressure Resistance: 63MPa, Ambient Temperature: -40 to 85℃, Protection Rating: IP67 Pressure Sensor: 0.1 to 0.6MPa / 0 to 6MPa / 0 to 25MPa / 0 to 40MPa, Accuracy: ±0.5% (F.S.), Oil Temperature: -40 to 100℃, Protection Rating: IP67

-

QT510 Flow Sensor--- Viscosity: 1 to 150 cSt (consult for high viscosity oil), Flow range: 0 to 20 L/min (42 MPa), 0 to 75 L/min (42 MPa), 0 to 300 L/min (42 MPa), 0 to 600 L/min (35 MPa), Accuracy: ±0.5% (F.S.), Seal: FKM, Oil temperature: -20 to 100°C, Ambient temperature: -20 to 100°C, Protection rating: IP67

-

S120 Oil Particle Counter (Optional) --- Visualize contaminants in oil using AI high-resolution digital image analysis! Detect bubbles and remove them from measurement values. The digital image particle counting technology can recognize particles of different shapes and measure a wide distribution from 4μ to over 100μ. Accuracy: ±1 ISO Code (ISO4406), Pressure Resistance: 35MPa (with pressure relief valve), Oil Temperature: 0 to 70°C, Protection Rating: IP65.

-

HHLP-24 Hydrostatic Liquid Level Sensor (Optional) --- Simply place it horizontally by directly inserting it into the deepest bottom surface of the target liquid tank, with no special installation required. It allows for real-time remote monitoring and measurement of the rising and falling liquid level. Water depth: 1 to 500 m (max. 700 m), Housing: SUS316L + Hastelloy or SUS316L, Cable material: PU / ETFE / PTFE.

Line up(2)

| Model number | overview |

|---|---|

| WLPROHSM-P1-T-Q1-A-Z | Pressure sensor (-0.1 to 0.6 MPa), temperature sensor (-50 to 200°C), flow sensor (0 to 20 L/min), oil particle counter (optional) + warning sound and stacked signal light. |

| WLPROQ | Custom Cloud Monitoring System Plug & Play - Configured to match the required sensors |

catalog(9)

Download All Catalogs

Company information

All handled products are primarily imported from the UK, Germany, and the USA, but we maintain close communication with overseas manufacturers and strive to respond quickly and in line with the times.

![Easy installation and operation remote monitoring system [Dalkonex]](https://image.mono.ipros.com/public/product/image/afd/2000609386/IPROS86510107785475691241.jpeg?w=280&h=280)