Basic Knowledge of Sheet Metal Processing - Punching Processing

Basic Knowledge of Sheet Metal Processing

We will introduce the basic knowledge of sheet metal processing.

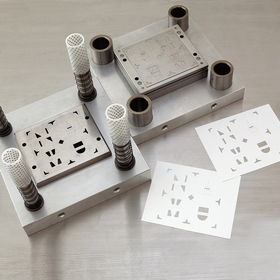

"Punching processing" is a type of "shearing processing" that is most commonly used in the work of separating materials into two or more parts. It refers to the process of cutting out parts of the required shape from sheet material using general-purpose molds. Drilling processing aims to create holes, while punching processing focuses on the parts that are removed, thus distinguishing it from drilling. NC turret punch press processing, often referred to as turret punch processing, involves cutting and punching various shapes through the positioning of molds set on a turret (rotating mechanism) and the XY coordinates of the table.

Inquire About This Product

basic information

●For more details, please contact us or download the catalog. 【Product Examples】 ○Parts for medical testing devices (including exterior and interior parts) ○Parts for measuring devices ○Parts for semiconductor manufacturing equipment ○Sheet metal parts for cash handling equipment ○Proprietary kiosk terminals

Price range

Delivery Time

Applications/Examples of results

For more details, please contact us or download the catalog.

catalog(1)

Download All CatalogsCompany information

Since its founding in 1969, Tsubota Technica has been a pioneering presence in Japan's precision sheet metal industry, working diligently to create high-precision, high-quality products that meet customer needs under the slogan "Selling satisfaction to our customers." As a company certified by an international quality assurance system, Tsubota Technica is committed to developing new technologies and products for an unlimited future, pursuing product creation that responds to the needs of the times, and contributing to the development of industry and society in the 21st century.