What are the reasons that Ishigaki Shoten Co., Ltd. is chosen for transforming "impossible" into "possible" with innovative copper bar processing?

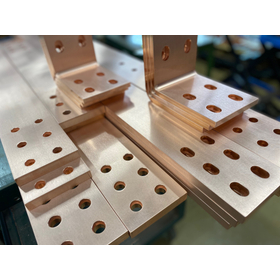

Ishigaki Shoten Co., Ltd. is an expert in copper bar (bus bar) processing that supports our customers' challenges. We realize various copper bar processing, from the smallest parts to large power receiving equipment. ■Features■ 【Industry Expertise】 Specialized in product parts for power industry receiving equipment and storage facilities! 【Copper Material Procurement】 Strong relationships with manufacturers and wholesalers, leveraging our background as a wholesaler to procure high-purity copper! 【Custom Orders】 Capable of handling special shapes through general-purpose machining by skilled artisans! 【High Quality & Precision】 Providing high-quality products born from advanced technology through the manufacturing of industrial battery and power supply components! ■Track Record■ 【Strong Trust from Listed Companies】 Boasting numerous transaction records, our latest copper processing technology is highly regarded. ■Strengths■ 【Experience in Large Product Deliveries】 Rich experience in manufacturing large items requiring precision processing, such as large power receiving equipment. 【Cost and Speed】 Adjusting the balance of delivery time, cost, and precision according to customer needs, achieving cost optimization while preventing excessive quality. 【Integrated Production】 Comprehensive response from procurement to processing, plating, and quality control through integrated production. *For more details, please refer to the downloadable materials.

Inquire About This Product

Related Videos

basic information

Choosing the optimal material and size when selecting copper bars significantly impacts product performance, cost, and delivery time. Below is a guide on how to choose the material and basic dimensions of copper bars. Material: C1100: Has high electrical conductivity and is generally suitable for electrical applications. C1020: Combines excellent thermal conductivity and workability, making it suitable for specific applications. Size (Cross-sectional area: Height × Width): Width: 12mm, 15mm, 20mm, 25mm, 30mm, 40mm, 50mm, 75mm, 100mm, 150mm, 200mm Height: 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm, 15mm, 20mm The cross-sectional area of the copper bar conforms to these basic dimensions, allowing for various combinations. When making your selection, consider the following points: Material cost: Choosing standard sizes can reduce costs. Delivery time: Selecting standard products can lead to quick arrangements and shorter delivery times.

Price information

It is calculated based on the daily copper base price.

Price range

P2

Delivery Time

P3

※*Please feel free to contact us as it may vary depending on the quantity and equipment operating status. We excel at urgent requests!!*

Applications/Examples of results

Components of high-voltage receiving equipment - Large, medium, and small transformers - Cubicles - Control panels / receiving panels - Disconnectors (DS) / switches / circuit breakers - Surge protectors - Breakers

Detailed information

-

Abundant material inventory (established as a wholesaler, with strong relationships with material manufacturers)

-

Our factory (producing in a clean, safe workplace with 5S).

-

Special bending processing is our specialty (twisting, edgewise).

-

Products of copper TIG welding (the skills of craftsmen are also being passed down to the younger generation)

catalog(3)

Download All CatalogsCompany information

We have been providing copper components to transformer and control panel manufacturers, delivering energy through copper and ensuring safety and security for society. As a result of walking alongside our customers throughout this process, we have become a "copper specialty processing company"! When our customers are truly in need, we respond as quickly as the same day, embodying the spirit of mutual support! ■ Overwhelming inventory ■ Craftsmanship that allows for the fastest processing and youthful, energetic power ■ Strong network with local plating partner companies We can perform various processing methods such as machining, pressing, welding, and brazing. Since we have established a production system for a wide variety of small quantities, ■ Small lots ■ Various sizes ■ Complex shapes can also be handled quickly. We aim to be a company that delivers energy to everyone through copper, and we look forward to your continued support.